ENGLISH

6) Pipe bending

Annealed copper pipe with small diameter (ø6.35 or ø9.52) can be easily bent manually. In

this case, secure large R(radius) for the bend section and gradually bend pipe. If annealed

copper pipe is large in diameter (ø15.88 or ø19.05), bend pipe with bender. Use bender

appropriate for the pipe diameter.

7) Brazing

In refrigerant piping, bending (in particular, acute bending) must be minimized to reduce

piping resistance. Bending is, however, necessary in some places by virtue of the installation

position of devices auxiliary to the packaged air conditioner, or of the building structure,

piping distance or finsishing appearance. If a more acute bend is required than that

attainable by pipe bender, perform brazing using ready-made elbow. Aside from this

function, brazing also serves to connect straight pipes, generally using ready-made sockets.

While brazing, protect piping against heat with wet cloth to avoid damaging valve packing or

burning thermal insulator with burner heat. While brazing, blow inert gas (nitrogen gas or

carbonic gas) to prevent formation of oxidation film in copper piping; otherwise, the

refrigerant circuit will clog. The blowing of nitrogen gas (or carbonic gas) through 3-way

valves is described in the following:

8) Refrigerant piping(Flare piping)

When connecting piping, be sure to keep piping dry(keep piping away from water), clean

(keep piping away from dust) and airtight (avoid refrigerant leakage).

When connecting piping on rainy days or making a through-hall in wall, take due care to

prevent water or plaster from entering piping.

13

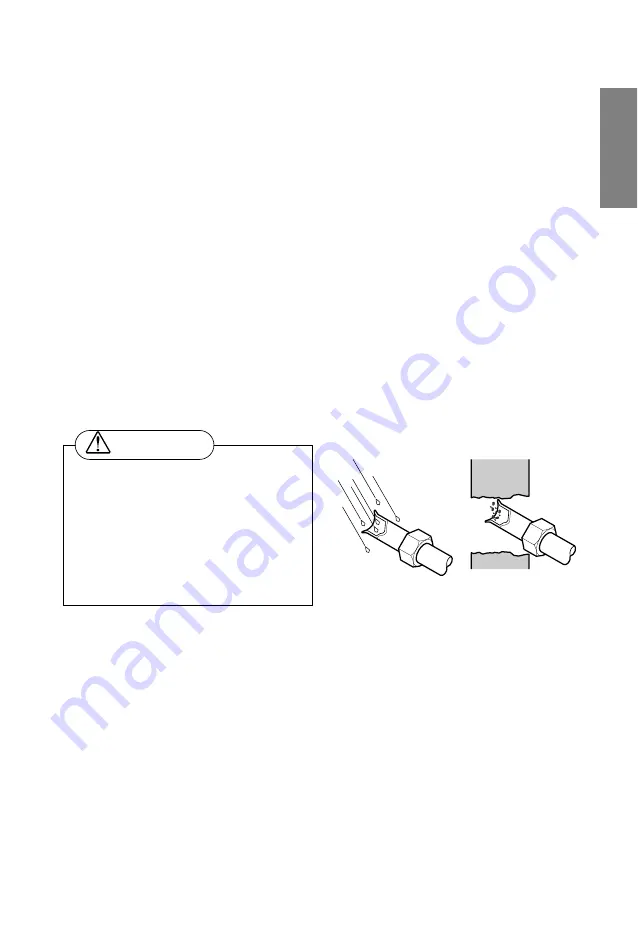

CAUTION

a. This procedure is designed to prevent

formation of oxidation film by filling piping

with inert gas. Note that excessive gas

pressure will generate pinholes at brazed

points.

(Nitrogen gas: Supply pressure

0.05~0.1kg/cm

2

G)

b. When supplying inert gas, be sure to open

one end of piping.

Water enters

Plaster enters