4-3 OLP (OVERLOAD PROTECTOR)

4-3-1 Definition of OLP

(1) OLP (OVERLOAD PROTECTOR) is attached to the

compressor and protects the motor by opening the

circuit to the motor if the temperature rises and

activating the bimetal spring in the OLP.

(2) When high current flows to the compressor motor, the

bimetal works by heating the heater inside the OLP, and

the OLP protects the motor by cutting off the current

flowing to the compressor motor.

4-3-2 Role of the OLP

(1) The OLP is attached to the sealed compressor used for

the refrigerator. It prevents the motor coil from being

started in the compressor.

(2) For normal operation of the OLP, do not turn the

adjustment screw of the OLP in any way.

4-4 TO REMOVE THE COVER PTC

(1) Remove the back cover of the mechanical area..

(2) Disconnect the two connectors on the top of the

compressor..

(3) Loosen two screws on compressor base.

(4) Use a flat screwdriver to pry off the cover.

(5) Assembly is the reverse order of disassembly.

- 11 -

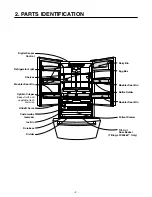

Part

Customer part

number

Lot code/

date code

330 FBYY

-S1 BOX98

12345678

Physical

termination

part number

Electrical

characteristics

part number

No. Name

Base, phenolic

(UL 94 V-0 rated)

Movable arm support, plated steel

Stationary contact support,

plated steel

Heater support, plated steel

Heater, resistance alloy

Disc, thermostatic alloy

Movable arm, spring temper

copper alloy

Contact, movable, silver on copper

Contact, stationary, silver on copper

Slug, plated steel

Cover, polyester

(UL 94 V -0 rated)

Pin connector, plated copper alloy

(To engage 2.33/2.66 mm dia. pin)

(OVERLOAD PROTECTOR

cross section)

Figure 18

1

2

3

Summary of Contents for LFD21860ST

Page 12: ...5 CIRCUIT DIAGRAM 12 ...

Page 36: ...8 5 MAIN PWB ASSEMBLY AND PARTS LIST 8 5 1 Main PWB Assembly 36 ...

Page 37: ...8 5 2 Replacement Parts List 37 ...

Page 38: ...8 5 3 PWB Assembly Display And Parts List 38 ...

Page 39: ...8 6 PWB DIAGRAM 8 6 1 PWB Main Assembly 39 ...

Page 40: ... 40 ...