7

Mechanical Installation

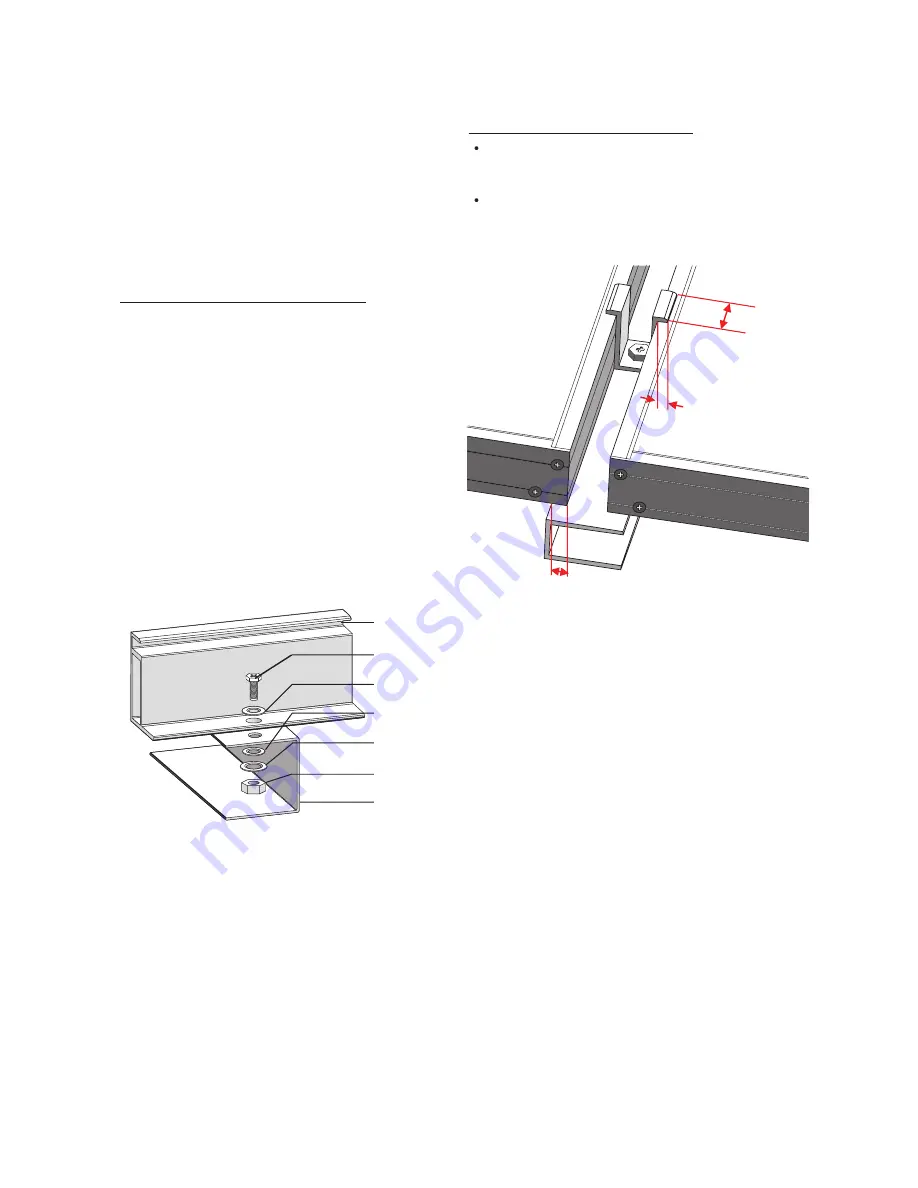

• A 6mm gap between module frames should be

allowed to avoid tension from thermal expansion.

• The solar module may be mounted using the

following methods: (*Torque:8~12Nm )

• When installing modules in heavy snow areas,

special care should be taken to install the modules

in a manner that provides sufficient design

strength while meeting local code requirements.

Bolt

Flat washer

Flat washer

Nut

Support

More than 40mm

More than 10mm

More than 10mm

Mounting by using clip or clamps

The module may be fastened to a support using

clips or clamps on both the long edge and the

short edge of the modules.

Specific information on location of clipping is

provided in ‘Mechanical Installation Scene’.

(Refer to next page)

Mounting by using frame bolts holes

• Secure the solar module to the structure using the

factory mounting holes.

• Four M6 stainless steel bolts, four nuts, four spring

washers, and eight flat washers are recommended

per solar module.

• For rear loads 5400Pa, modules should be

fastened with four M8 stainless steel bolts, four

nuts, four spring washers, and eight flat washers.

• The module may be fastened to a support using

both the outer and inner bolt holes of the frame.

• Each module should be securely fastened at a

minimum 4 points on two opposite sides.

• Specific information on the solar module

dimensions and location of mounting holes is

provided in ‘Product Specifications’.

• Tighten the bolt securely using this combination.

Place spring washer between Flat washer and Nut.

Module frame

Spring washer

Summary of Contents for LG280N1C-G4

Page 13: ......