- 4-17 -

DECK MECHANISM ADJUSTMENT

Purpose: To obtain compatibility with the other VCR(VCP) Models.

5-2. Confirm that the tape passes smoothly

between the Take-up Guide and Pinch

Roller(using a mirror or the naked eye).

1) After completing Step 5-1.(Preliminary Adjustment), check

that the tape passes around the Take-up Guide and Pinch

Roller without folding or curling at the top or bottom.

(1) If folding or curling is observed at the bottom of the

Take-up Guide then slowly turn the Tilt Adjustment

Screw(C) in the clockwise direction.

(2) If folding or curling is observed at the top of it then

slowly turn the Tilt Adjustment Screw(C) in the

counterclockwise direction.

NOTE:

Check the RF envelope after adjusting the A/C Head, if the

RF waveform differs from Fig. C-5-4, performs Precise

Adjustment to flat the RF waveform.

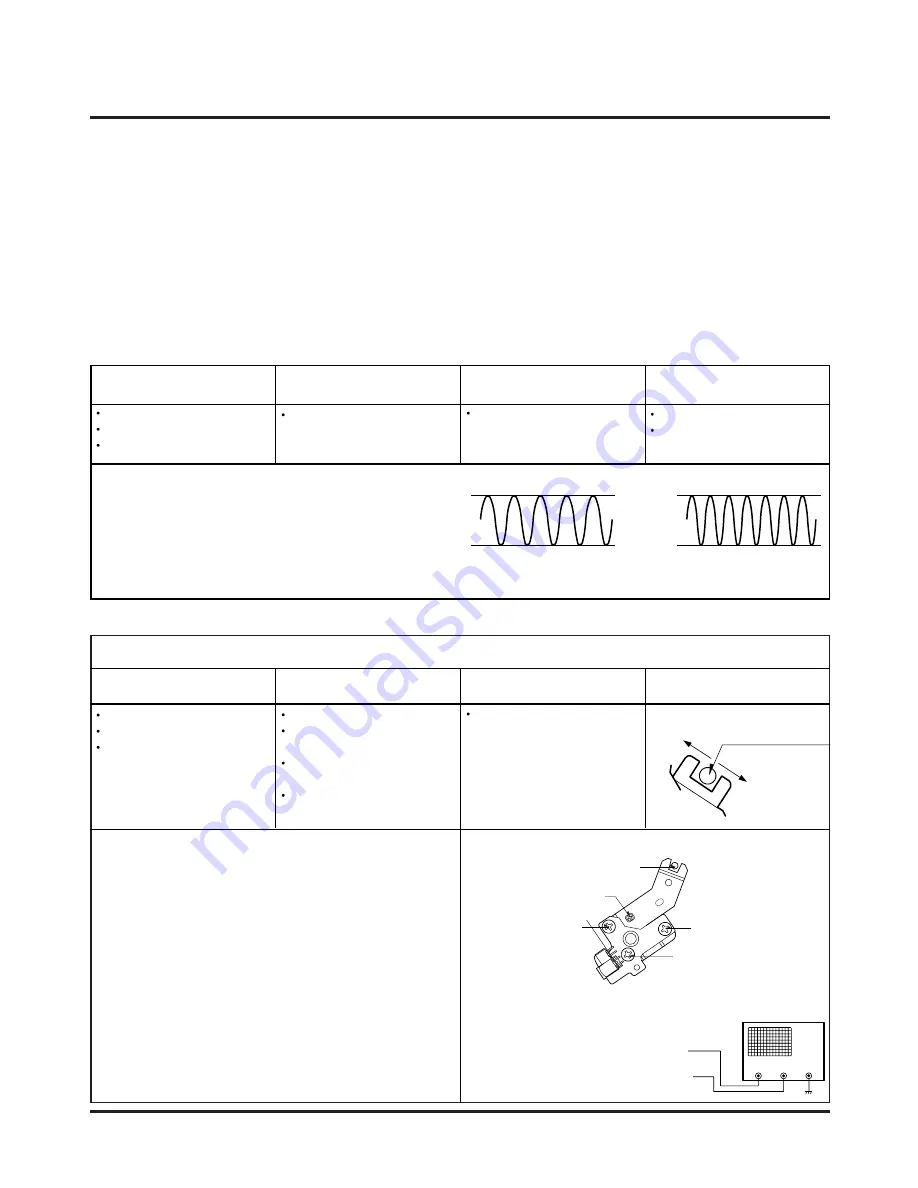

Test Equipment/ Fixture

Oscilloscope

Alignment Tape(SP)

Screw ) Type 5mm

Connection Point

Audio output jack

Test Conditions

(Mechanism Condition)

Play an Alignment Tape

1KHz, 7KHz Sections

Adjustment Point

Azimuth Adjustment Screw(A)

Height Adjustment Screw(B)

1) Connect the probe of the oscilloscope to Audio Output

Jack.

2) Alternately adjust the Azimuth Adjustment Screw(A) and

the Tilt Adjustment Screw(C) for maximum output of the

1KHz and 7KHz segments, while maintaining the flattest

envelope differential between the two frequencies.

Adjustment Procedure

5-3. Precise Adjustment (Azimuth adjustment)

6. X-Value Adjustment

Fig. C-5-4

1KHZ

Oscilloscope

Alignment Tape(SP only)

Screw ) Type 5mm

CH-1: PB RF Envelope

CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

Head Switching Output

Test Point

RF Envelope Output Test

Point

Test Conditions

(Mechanism Condition)

Play an Alignment Tape

Adjustment Point

Connection Point

Test Equipment/ Fixture

Adjustment Procedure

1) Release the Automatic Tracking to run long enough for

tracking to complete it s cycle.

2) Loosen the Fixed Mounting Screw and move the Base

Assembly A/C Head in the direction as shown in the dia-

gram to find the center of the peak that allows for the max-

imum waveform envelope.

This method should allow the 31 m Head to be centrally

located over the 58 m tape track.

3) Tighten the Base Assembly A/C Head mounting Screw.

7KHZ

A:Maximum

B:Maximum

Left

Right

Groove at the

Base A/C

Height Adjustment Screw(B)

Tilt Adjustment Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment Hole

Fixed Screw

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST POINT

Connection Diagram

Adjustment Diagram

CH-1 CH-2

Summary of Contents for LH-C6230P

Page 10: ... 2 1 SECTION 2 AUDIO PART ...

Page 12: ... 3 2 VCR ELECTRICAL TROULBESHOOTING ...

Page 13: ... 3 3 ...

Page 27: ... 5 1 DVD ELECTRICAL TROUBLESHOOTING 1 Test debug flow SECTION 5 DVD PART ...

Page 28: ... 5 2 ...

Page 29: ... 5 3 ...

Page 30: ... 5 4 ...

Page 31: ... 5 5 ...

Page 32: ... 5 6 ...

Page 36: ... 5 10 2 Tray close waveform 3 Tray open waveform ...

Page 38: ... 5 12 6 LASER POWER CONTROL RELATED SIGNAL NO DISC CONDITION 7 DISC TYPE JUDGEMENT WAVEFORM ...

Page 39: ... 5 13 ...

Page 40: ... 5 14 8 FOCUS ON WAVEFORM ...

Page 41: ... 5 15 9 SPINDLE CONTROL WAVEFORM NO DISC CONDITION ...

Page 42: ... 5 16 10 TRACKING CONTROL RELATED SIGNAL System checking ...

Page 43: ... 5 17 11 RF WAVEFORM 12 MT1379 AUDIO OPTICAL AND COAXIAL OUTPUT ASPDIF ...

Page 44: ... 5 18 13 MT1379 VIDEO OUTPUT WAVEFORM 1 Full colorbar signal CVBS 2 Y ...

Page 45: ... 5 19 3 C 14 AUDIO OUTPUT FORM AUDIO DAC 1 Audio related Signal ...

Page 46: ... 5 20 MEMO ...

Page 49: ...2 2 2 3 BLOCK DIAGRAM ...

Page 50: ...2 4 2 5 AUDIO SHEMATIC DIAGRAMS U COM SCHEMATIC DIAGRAM ...

Page 51: ...2 6 2 7 FUNCTION POWER SCHEMATIC DIAGRAM ...

Page 52: ...2 8 2 9 MAIN AMP SCHEMATIC DIAGRAM ...

Page 53: ...2 10 2 11 WIRING DIAGRAM ...

Page 55: ...2 14 2 15 PRINTED CIRCUIT DIAGRAM MAINAMP FRONT P C BOARD SOLDER SIDE ...

Page 56: ...2 16 2 17 MAINAMP FRONT P C BOARD COMPONENT SIDE ...

Page 57: ...2 18 2 19 FUNCTION POWER P C BOARD SOLDER SIDE ...

Page 58: ...2 20 2 21 FUNCTION POWER P C BOARD COMPONENT SIDE ...

Page 59: ...3 17 3 18 VCR SHEMATIC DIAGRAMS SYSTEM SCHEMATIC DIAGRAM ...

Page 60: ...3 19 3 20 A AUDIO V VIDEO SCHEMATIC DIAGRAM ...

Page 62: ...3 23 3 24 TU IF ACSS SCHEMATIC DIAGRAM ...

Page 63: ...3 25 3 26 HIFI TUNER SCHEMATIC DIAGRAM ...

Page 64: ...3 27 3 28 A V JACK SCART SCHEMATIC DIAGRAM ...

Page 66: ...3 31 3 32 PRINTED CIRCUIT DIAGRAMS TUNER P C BOARD ...

Page 67: ...3 33 3 34 VCR P C BOARD ...

Page 68: ...3 35 3 36 VCR P C BOARD ...

Page 69: ...5 22 5 21 DVD PART SCHEMATIC DIAGRAMS MPEG SCHEMATIC DIAGRAM ...

Page 70: ...5 23 5 24 SERVO SCHEMATIC DIAGRAM ...

Page 71: ...5 25 5 26 AUDIO SCHEMATIC DIAGRAM ...

Page 72: ...5 27 5 28 INTERFACE SCHEMATIC DIAGRAM ...

Page 73: ...5 29 5 30 VOLTAGE SHEET IC TR ...

Page 74: ...5 31 5 32 PRINTED CIRCUIT DIAGRAM DVD P C BOARD SOLDER SIDE ...

Page 75: ...5 33 5 34 DVD P C BOARD COMPONENT SIDE ...

Page 77: ...SECTION 4 MECHANSIM OF VCR PART ...

Page 89: ... 4 12 ...

Page 101: ... 4 24 ...

Page 113: ......