- 1-3 -

■

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong magnet-

ism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M

Ω

)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent sta-

tic electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

CLEARING MALFUNCTION

You can reset your unit to initial status if malfunction occur(button malfunction, display, etc.).

Using a pointed good conductor(such as driver), simply short the RESET jump wire on the inside of

the volume knob for more than 3 seconds.

If you reset your unit, you must reenter all its settings(stations, clock, timer)

NOTE:

1. To operate the RESET jump wire, pull the volume rotary knob and release it.

2. If you wish to operate the RESET jump wire, it is necessary to unplug the power cord.

Resistor

(1 Mohm)

Conductive

Sheet

Resistor

(1 Mohm)

Armband

RESET jump wire

VOLUME

VOLUME KNOB

DOWN

UP

Summary of Contents for LM-U2350A

Page 7: ... 1 6 ...

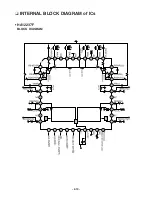

Page 17: ... 2 10 INTERNAL BLOCK DIAGRAM of ICs HA12237F BLOCK DIAGRAM ...

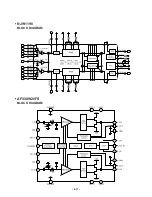

Page 18: ... 2 11 NJW1190 BLOCK DIAGRAM AF330W20FS BLOCK DIAGRAM ...

Page 20: ... 2 13 AF350W01FS BLOCK DIAGRAM PIN CONFIGURATION ...

Page 22: ...2 15 2 16 BLOCK DIAGRAM ...

Page 23: ...2 17 2 18 WMA_USB BLOCK DIAGRAM ...

Page 24: ...2 19 2 20 SCHEMATIC DIAGRAMS FRONT SCHEMATIC DIAGRAM ...

Page 25: ...2 22 2 21 MAIN SCHEMATIC DIAGRAM ...

Page 26: ...2 23 2 24 DECK SCHEMATIC DIAGRAM ...

Page 27: ...2 26 2 25 MIC SCHEMATIC DIAGRAM ...

Page 28: ...2 27 2 28 USB_AUX2_H P SCHEMATIC DIAGRAM ...

Page 29: ...2 30 2 29 WOOFER AMP SCHEMATIC DIAGRAM ...

Page 30: ...2 31 2 32 AMP SCHEMATIC DIAGRAM ...

Page 31: ...2 34 2 33 POWER SCHEMATIC DIAGRAM ...

Page 32: ...2 35 2 36 POWER SCHEMATIC DIAGRAM ...

Page 33: ...2 37 2 38 SUB POWER SCHEMATIC DIAGRAM ...

Page 34: ...2 39 2 40 CDP SCHEMATIC DIAGRAM ...

Page 35: ...2 41 2 42 USB SCHEMATIC DIAGRAM ...

Page 36: ...2 43 2 44 WIRING DIAGRAMS ...

Page 37: ... PRINTED CIRCUIT DIAGRAMS MAIN P C BOARD 2 45 2 46 ...

Page 38: ...2 47 2 48 MAIN AMP P C BOARD ...

Page 39: ...2 49 2 50 MAIN AMP P C BOARD ...

Page 40: ...2 51 2 52 FRONT P C BOARD ...

Page 41: ...2 53 2 54 CDP P C BOARD ...

Page 42: ...2 55 2 56 CDP P C BOARD ...

Page 43: ...2 57 2 58 POWER P C BOARD ...

Page 44: ...2 59 2 60 POWER P C BOARD ...

Page 45: ...2 61 2 62 SUB POWER P C BOARD ...

Page 46: ...2 63 2 64 WOOFER AMP P C BOARD ...

Page 47: ...2 65 2 66 ...

Page 55: ... 4 4 ...