Summary of Contents for LMVM2033BM

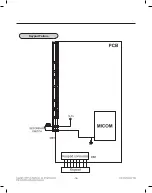

Page 16: ... 16 Keypad Failure ...

Page 42: ...2004 2381 W262 2008 2006 EV CONTROLLER PARTS MODELS Customer Model Product Code SVC Model ...

Page 44: ...W102 4000 4001 4004 4002 4003 4002 LATCH BOARD PARTS EV ...

Page 47: ...6011 6010 6009 6008 VINYL BAG MBM5 MBM4 INSTALLATION PARTS EV ...

Page 48: ......