6-4 REFRIGERATION CYCLE

6-4-1 Cleaning

There is no need for routine condenser cleaning in normal Home operating environments. If the environment is particularly

greasy or dusty, or there is significant pet traffic in the home, the condenser should be cleaned every 2 to 3 months to

ensure maximum efficiency.

If you need to clean the condenser:

●

Remove the mechanical cover.

●

Use a vacuum cleaner with a soft brush to clean the grille, the open areas behind the grille and the front surface area of

the condenser.

●

Replace the mechanical cover.

- 23 -

▼

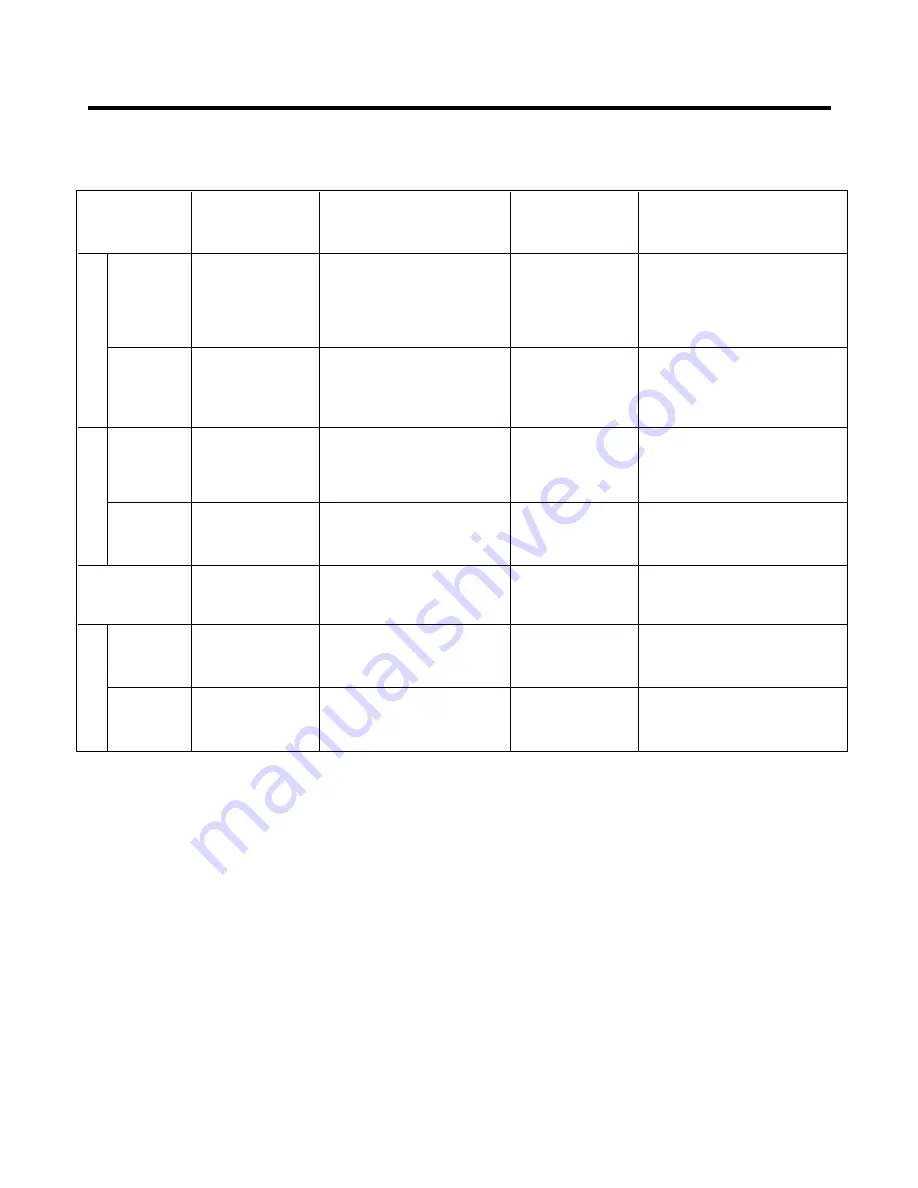

Troubleshooting Chart

PARTIAL

Freezer

Low flowing sound of

A little higher

• Refrigerant level is low due

LEAKAGE

compartment and

Refrigerant is heard and

than ambient

•

to a leak.

Refrigerator don't

frost forms in inlet only.

temperature.

• Normal cooling is possible by

cool normally.

•

restoring the normal amount of

•

refrigerant and repairing the leak.

COMPLETE

Freezer

Flowing sound of refrigerant

Equal to ambient

• No discharging of Refrigerant.

LEAKAGE

compartment and

is not heard and frost isn't

temperature.

• Normal cooling is possible by

Refrigerator don't

formed.

•

restoring the normal amount of

cool normally.

•

refrigerant and repairing the leak.

PARTIAL

Freezer

Flowing sound of refrigerant

A little higher

• Normal discharging of the

CLOG

compartment and

is heard and frost forms

than ambient

•

refrigerant.

Refrigerator don't

in inlet only.

temperature.

• The capillary tube is faulty.

cool normally.

WHOLE

Freezer

Flowing sound of refrigerant

Equal to ambient

• Normal discharging of the

CLOG

compartment and

is not heard and frost isn't

temperature.

•

Refrigerant.

Refrigerator don't cool. formed.

MOISTURE

Cooling operation

Flowing sound of refrigerant

Lower than

• Cooling operation restarts

CLOG

stops periodically.

is not heard and frost melts.

ambient

•

when heating the inlet of the

temperature.

•

capillary tube.

COMP-

Freezer and

Low flowing sound of

A little higher

• Low pressure at high side

RESSION

Refrigerator

refrigerant is heard and

than ambient

•

of compressor due to low

don't cool.

frost forms in inlet only.

temperature.

•

refrigerant level.

NO COMP-

No compressing

Flowing sound of refrigerant

Equal to ambient

• No pressure in the high

RESSION

operation.

is not heard and there is

temperature.

•

pressure part of the

no frost.

•

compressor.

CAUSE

TEMPERATURE

OF THE

COMPRESSOR

REMARKS

STATE OF

THE UNIT

STATE OF THE

EVAPORATOR

LEAKAGE

CLOGGED

BY

DUST

DEFECTIVE

COMPRESSION

www.Appliantology.org