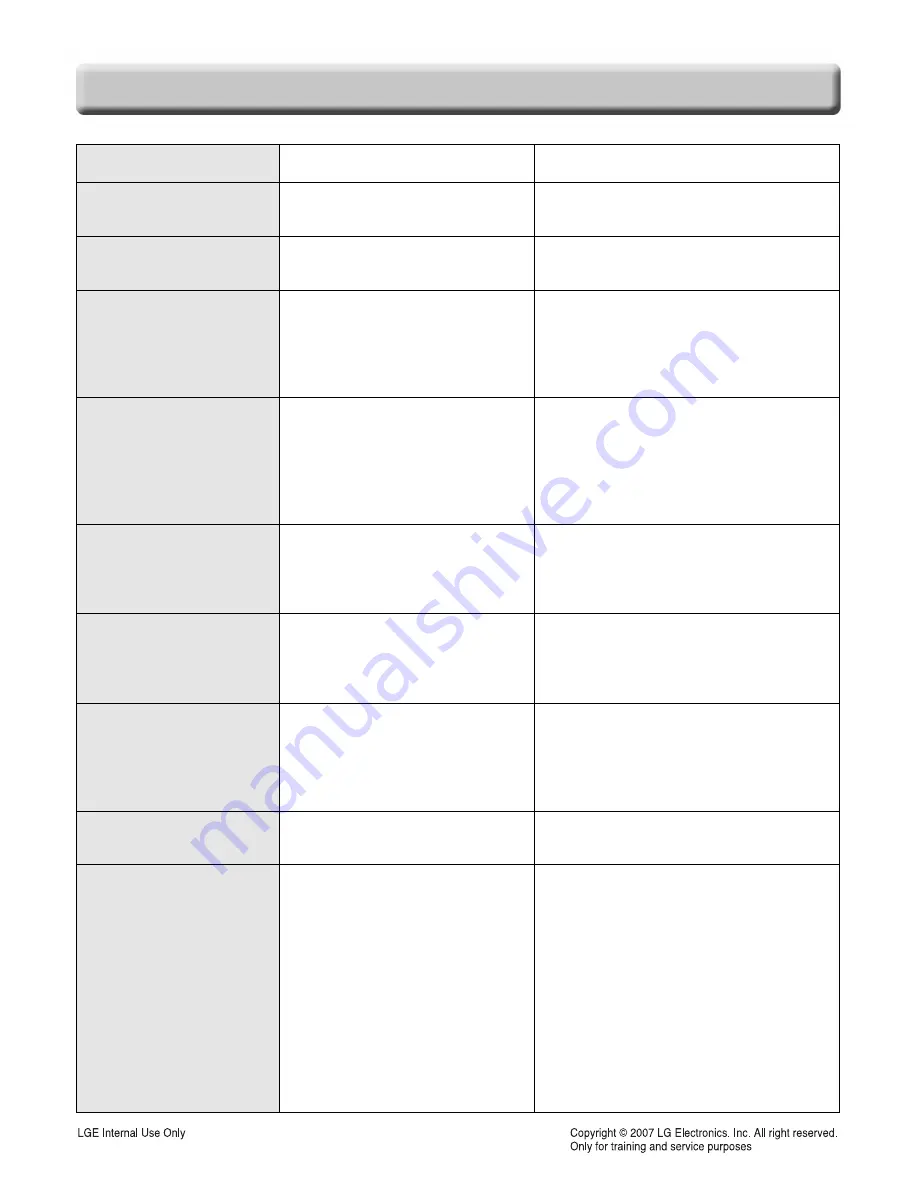

8-2

TROUBLE SHOOTING

Electronic timer will not

accept Programming.

Electronic timer will not

accept Programming.

Clock and timer not working

Oven does not bake

(Selection is set for to BAKE

or TIMED BAKE)

Oven does not Broil

Overheating or

“runaway” oven

Oven door will not open or

latch.

Premature burnout of bake

element

Oven door difficult to open

• Failed main power control board

• Failed main power control board

• Power outage

• Loose or bad wiring

• Defective BAKE element

• Defective electronic clock

• Door switch sensing error

• Loose or bad wiring

• Defective BROIL element

• Defective Power Control Board

• Loose or bad wiring to latch

system

• Defective Oven Sensor

• Bad Power Control Board(PCB)

• Defective latch mechanism.

• Defective(bent)door latch lever.

• Oven is still hot. Cool-down period

after self-clean cycle not complete

• Improper use of oven(e.g. being

used to heat the home)

• Worn or broken broil stop roller.

• Replace power control board(PCB)

• Replace power control board(PCB)

• Verify power is present at unit.

• Verify that the circuit breaker is not tripped

• Replace household fuse, but do not fuse

capacity

• Refer to Owner’s manual instructions

• Verity all connections are clean and tight,

replace broken wire

• Test and/or replace BAKE element.

• Replace power control board(PCB)

• Test door switch and check the point of

contact between door and door switch

• Verity all connections are clean and tight,

replace broken wire

• Test and/or replace BAKE element.

• Replace power control board(PCB)

• Repair or replace wiring

• Test and/or replace Oven Sensor

• Test and/or replace PCB

• Replace door latch system.

• Replace latch lever

• This is normal. Wait until LOCK icon goes

out.

• Use oven for baking only

• Replace oven door hinge

PROBLEMS

POSSIBLE CAUSES & FAULTS

SOLUTIONS