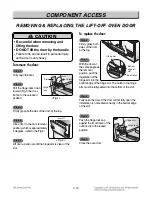

1. Unplug range or disconnect power.

2. Pull the range out of its mounting location so that

you can access the rear of the unit.

3. Remove the rear panel from the unit.

(See step 3 on page 3-2 for procedure)

4. Remove the 2 screws of

power cord assembly

box and 1 ground screw.

5. Set the box aside

6. Cut the 9 points of flange and remove the bake

heater cover.

3-7

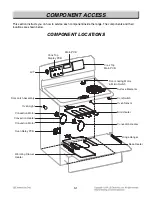

COMPONENT ACCESS

7. Bend the insulation glass fiber up.

8. Remove two screws

and bend up two flanges

9. Carefully pull the hidden bake element and its

mounting bracket out of the range.

REPLACING THE MOUNTING BRACKET

1. Drive the two screws

REMOVING THE HIDDEN BAKE ELEMENT

REMOVING THE HIDDEN BAKE ELEMENT

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Hidden bake element

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Total 9 points

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Screw

Flanges