6-5-1 SEALED SYSTEM DIAGNOSIS

- 17 -

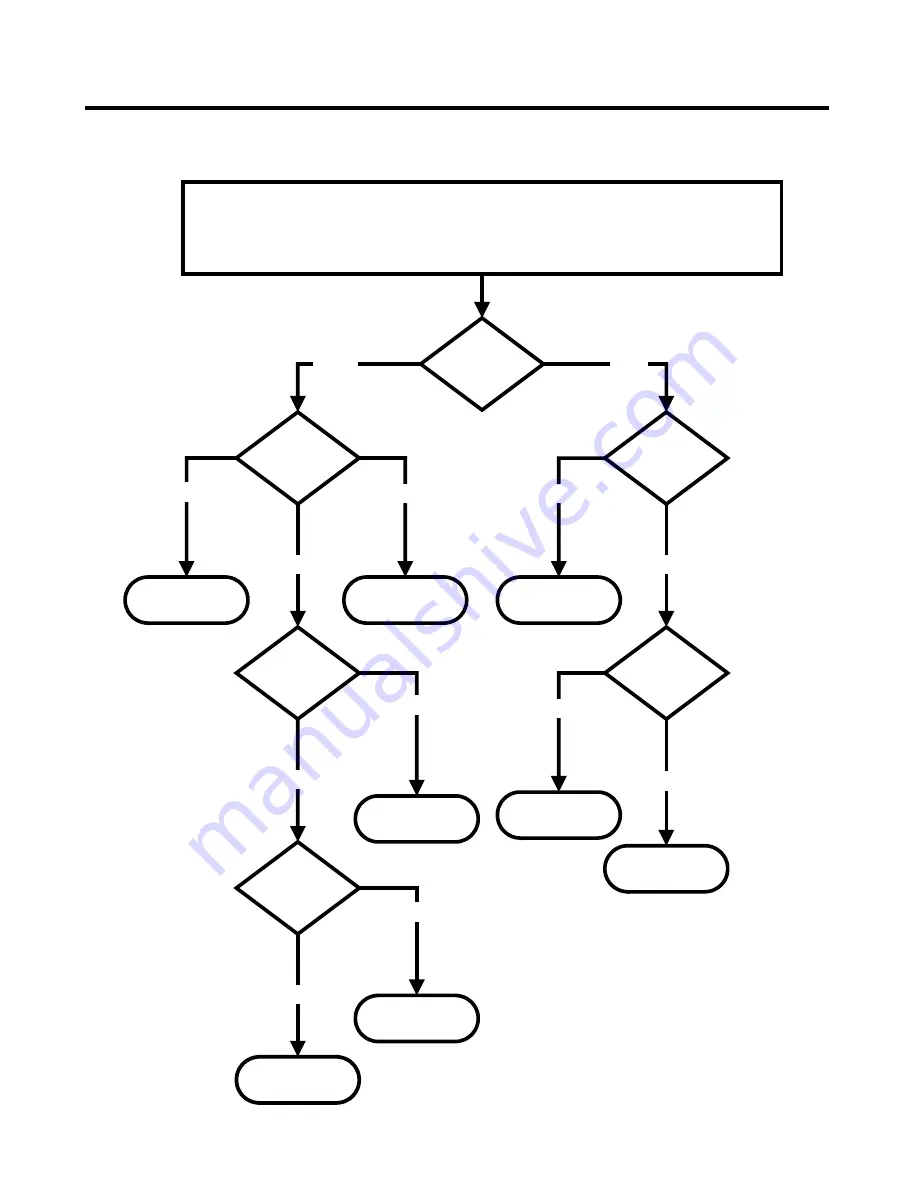

“Not Cooling” Complaint

All components operating, No airflow problems, Not frosted up as a defrost problem

problem has been isolated to sealed system area

Frost

Pattern?

Equalization

Test

Partial

Very Fast

Inefficient

Compressor

Partial

Restriction

Complete

Restriction

Equalization

Test

Condenser

Temperature

None

Very Fast

Very Slow

Very Slow

Hotter than Normal

Air/Low Side

Leak

Loss of Change

Compressor Not

Pumping

Cap Tube

Sound

Room Temperature

Trace of Oil

Undercharge

Leak

Yes

No

Faint

Fast

None to Weak

(The equalization test is trying to restart a compressor using a start kit after it has been operating.)

Summary of Contents for LRFD21855ST

Page 11: ...5 CIRCUIT DIAGRAM 11 ...