4-1

COmpONENT TEST

Before testing any components, perform the following checks:

NOTE:

1. The most common cause for control failure is corrosion on

connectors.

Therefore, disconnecting and reconnecting wires will be

necessary throughout test procedures.

2. ALL units in the first few days of use should be checked for mis-

wiring or loose connections.

1. All/tests/checks should be made with a VOM or DVM having a

sensitivity of 20,000 ohms per-volt DC, or greater.

2. Check all connections before replacing components, looking for broken

or loose wires, failed terminals, or wires not pressed into connectors far

enough.

3. Resistance checks must be made with the power cord unplugged from

the outlet, and with the wiring harness or connectors disconnected.

Components

Test procedures

Results

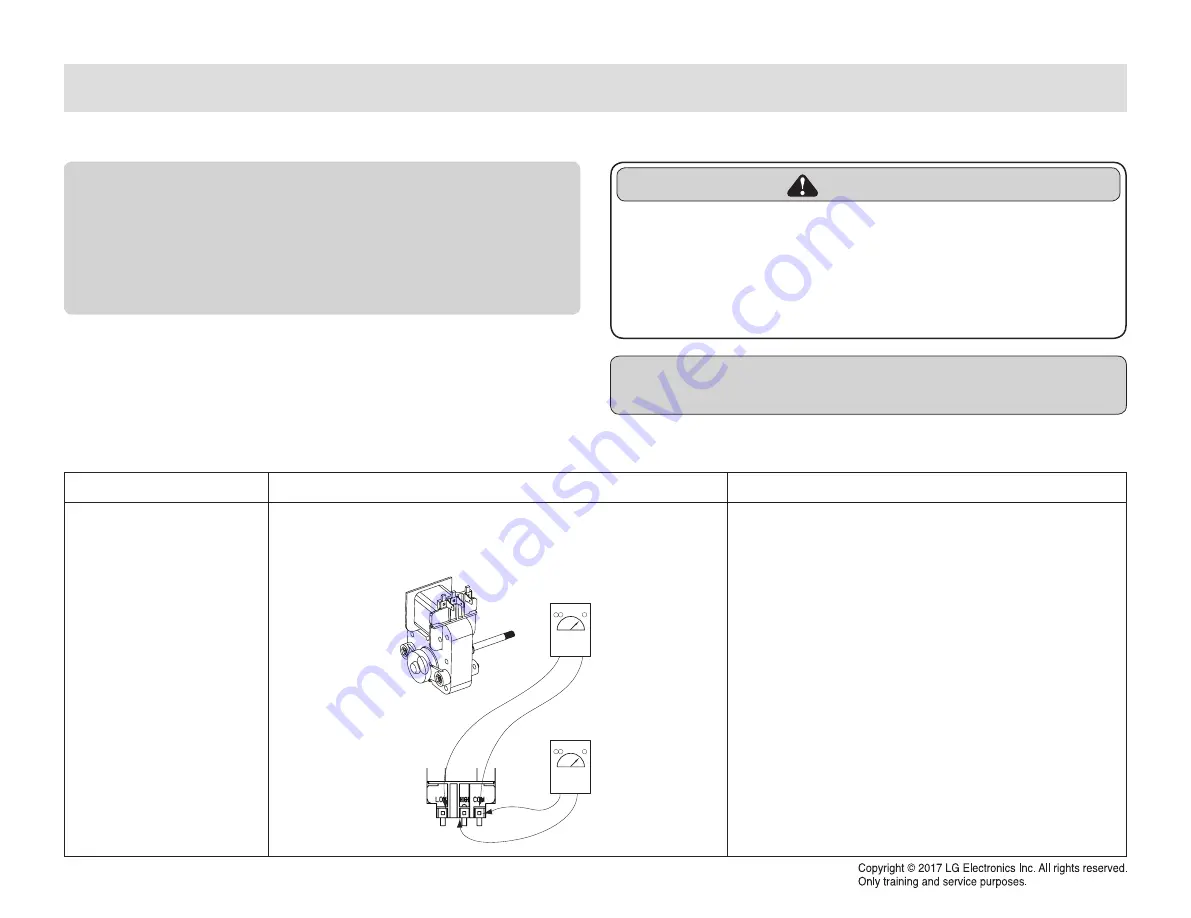

Convection Motor

1. Refer to page 3-15 for the servicing procedure

2. Measure the resistance

(Multiple meter scale: R x 1)

Normal: Approximately

Low-COM : 30 Ω

High-COM : 23.7 Ω

If not replace

Abnormal: Infinite (open)

below 5Ω (shorted)

WARNING

• Disconnect power supply cord from the outlet before

servicing

• Replace all panels and parts before operating

• Reconnect all grounding devices after servicing

- Failure to do so can result in death or electric shock

NOTE: Below Ω value were tested at room temperature

(77F/25°C)

Summary of Contents for LUTE4619SN

Page 68: ...5 3 Lower Selfclean Oven Lamp Bridge Cook top Element CR Cook top Element ...

Page 69: ...5 4 RR Cook top Element RF Cook top Element Upper BROIL EASY Clean Lower Broil ...

Page 70: ...5 5 Upper BAKE WARM Clock Display On ...

Page 71: ...6 1 COMPOSITION OF CONTROL Wiring Diagram ...

Page 74: ...6 4 COMPOSITION OF CONTROL P N EBR80595411 Oven Relay PCB CN53 CN52 CN51 ...

Page 75: ...6 5 COMPOSITION OF CONTROL SMPS PCB Touch PCB P N EBR80595701 P N EBR82864102 CN02 CN01 CN1 ...

Page 107: ...COOKTOP PARTS EV 330M 3204 3204 3204 3204 3204 3215 3056 3079 3022 330H 330S 5700 3014 3016 ...

Page 110: ......