Summary of Contents for LX-D2560A

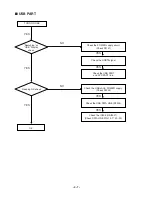

Page 7: ... 1 6 ...

Page 11: ......

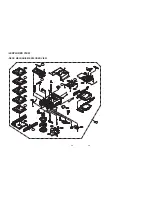

Page 12: ... 2 7 4 SPEAKER EXPLODED VIEW 758 757 A700 756 754 755 753 752 751 750 759 ...

Page 13: ... 2 8 ...

Page 26: ... 3 13 INTERNAL BLOCK DIAGRAM of ICs UTC MC4580 PIN CONFIGURATION TEST CIRCUIT ...

Page 28: ... 3 15 HY57V281620ETP FUNCTIONAL BLOCK DIAGRAM FAN8082D Internal Block Diagram ...

Page 29: ... 3 16 BU2090 Block diagram ...

Page 30: ... 3 17 HA12237F BLOCK DIAGRAM ...

Page 31: ... 3 18 BA3308 BA3308F BLOCK DIAGRAM BA3308 BA3308F ...

Page 32: ... 3 19 TAS5142 BLOCK DIAGRAM ...

Page 33: ... 3 20 HT1200 4 SYSTEM BLOCK DIAGRAM ...

Page 34: ... 3 21 HT1200 4 FUNCTIONAL BLOCK DIAGRAM ...

Page 35: ... 3 22 CS5340 BLOCK DIAGRAM BU4052 BLOCK DIAGRAM ...

Page 36: ... 3 23 STR S6757IF1905 BLOCK DIAGRAM STR A6200 BLOCK DIAGRAM ...

Page 37: ... 3 24 ...

Page 38: ...3 25 3 26 WIRING DIAGRAM ...

Page 41: ...3 31 3 32 µ COM INTERFACE PWM SCHEMATIC DIAGRAM ...

Page 42: ...3 33 3 34 6CH_AMP SCHEMATIC DIAGRAM ...

Page 43: ...3 35 3 36 FRONT SCHEMATIC DIAGRAM ...

Page 44: ...3 37 3 38 SMPS SCHEMATIC DIAGRAM ...

Page 45: ...3 39 3 40 DECK SCHEMATIC DIAGRAM ...

Page 46: ...3 41 3 42 PRINTED CIRCUIT DIAGRAMS MAIN P C BOARD ...

Page 47: ...3 43 3 44 MAIN P C BOARD ...

Page 48: ...3 45 3 46 FRONT P C BOARD ...

Page 49: ...3 47 3 48 SMPS P C BOARD ...

Page 50: ...3 49 3 50 DECK P C BOARD ...

Page 51: ......

Page 63: ... 4 12 TRACKING SIGNAL RF WAVEFORM 1 Tro 2 Tr 3 Tr ...

Page 64: ... 4 13 DISK TYPE JUGEMENT WAVEFORM 1 F 2 FDO 3 SVRRF DVD CD ...

Page 65: ... 4 14 ...

Page 66: ...4 15 4 16 DVD SCHEMATIC DIAGRAMS MPEG SCHEMATIC DIAGRAM ...

Page 67: ...4 17 4 18 RF SERVO SCHEMATIC DIAGRAM ...

Page 68: ...4 19 4 20 AV SCHEMATIC DIAGRAM ...

Page 69: ...4 21 4 22 USB PC LINK SCHEMATIC DIAGRAM ...

Page 70: ...4 23 4 24 DVD PRINTED CIRCUIT DIAGRAMS DVD MAIN P C BOARD ...

Page 71: ...4 25 4 26 DVD MAIN P C BOARD ...

Page 77: ...5 6 ...

Page 79: ......