50

PRDCAM

AHU Communication Kit Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

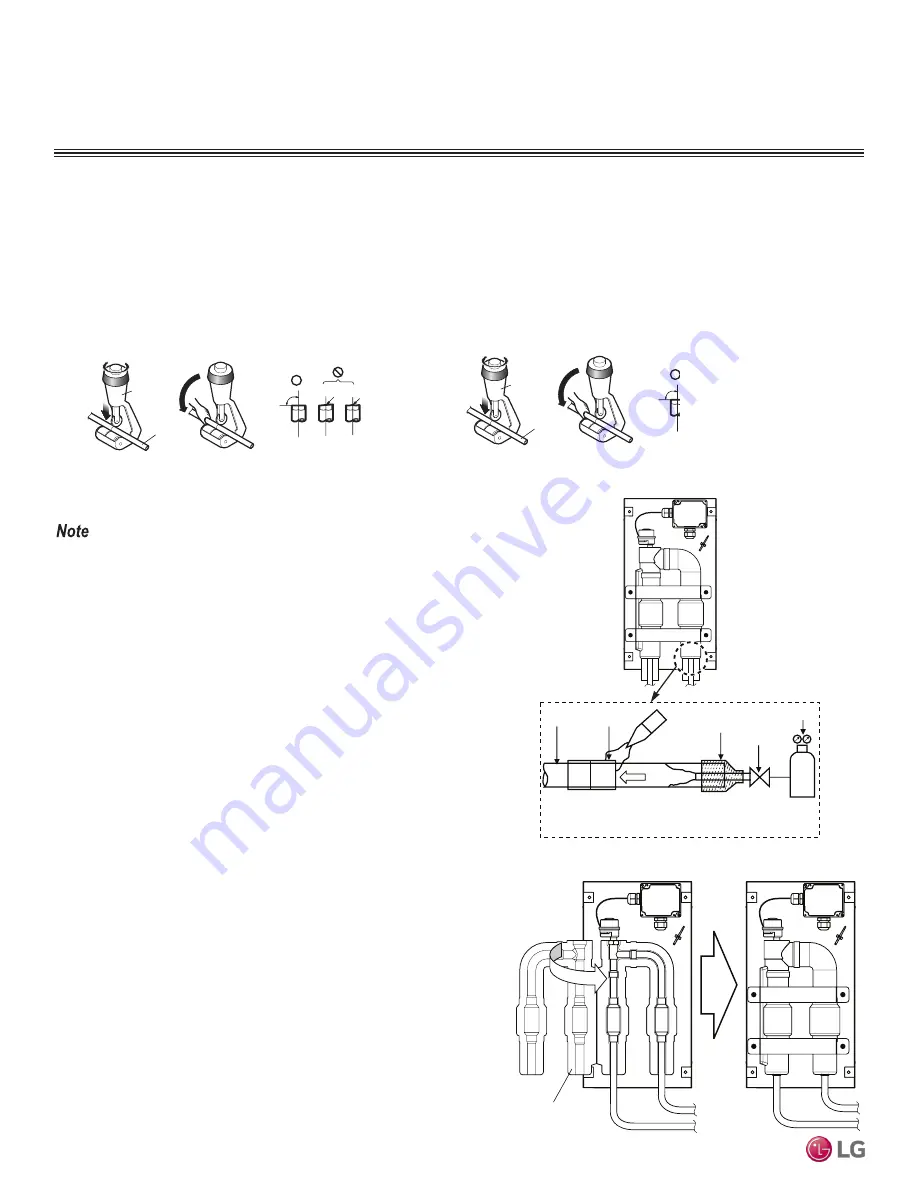

EEV KIT INSTALLATION

Liner

Fold

A

B

C

D

f

Brazing

E

F

A Refrigerant Piping

B Area to be Brazed

C Tape

D Hands-On Valve

E Pressure-Reducing Valve

F Nitrogen

Insulating the Piping

1. After brazing is complete, place the Pipe Insulation back on the

EEV Assembly. Peel off the liner, fold the insulation as shown in

the figure at right, and press down to seal.

2. Fully insulate the field piping up to the EEV Assembly. To avoid

condensation, make sure there are no gaps between the field

piping insulation and the EEV Assembly insulation. Finish the

connection with tape.

3. To secure the EEV Assembly, re-install the two (2) pipe support

brackets using the four (4) M4 screws.

Brazing

• Use a nitrogen purge set to 0.02 MPa while brazing.

Brazing without a nitrogen purge will create a large amount of

oxidization on the inside of the pipes, adversely affecting valves and

compressors in the refrigerating system and preventing normal system

operation�

• When brazing the field piping to the EEV Kit Assembly, use a wet cloth to pro-

tect and ensure that the main EEV body temperature does not exceed 248°F.

• Make sure that the other parts such as electrical box, support ties, and wiring

are also protected from direct flames during brazing.

• After brazing is complete, use medical grade dry nitrogen and pressure

test the refrigerant piping system to a minimum of 550 psi for a period of 24

hours. Pressurize the liquid, low pressure vapor, and high pressure vapor

pipes (heat recovery systems only) of the air-source / water-source units

concurrently. The test must be done with the air-source / water-source unit

service valves closed. (For more details, refer to the manual of the respective

air-source / water-source installation manuals.)

Figure 23: Brazing Field Piping to EEV Assembly.

Brazing and Insulating the Piping

Figure 24: Installing the Insulation.

Cutting Pipe

1 Use a copper pipe cutter to cut the pipe in a straight line.

2 When cutting, tilt the pipe end downward to prevent

burrs from getting inside the pipe. After cutting, use

a reamer to remove any burrs from inside the pipe.

Copper

pipe cutter

90°

Incline Roughness

Pipe

Copper

pipe cutter

90°

Incline Roughness

Pipe

Notes:

The presence of burrs can result in refrigerant leakage.

Remove any burrs with a reamer.

Cutting dust could lead to malfunctioning if it gets

inside the pipe.