Summary of Contents for RC7055*P*Z

Page 9: ...PROGRAM CYCLE 4 9 ...

Page 12: ...INSTALLATION INSTRUCTIONS 5 12 ...

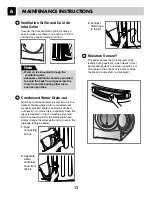

Page 14: ...MAINTENANCE INSTRUCTIONS 6 1 2 4 5 6 7 CAUTION 3 8 14 ...

Page 15: ...COMPONENT TESTING TIPS 7 15 ...

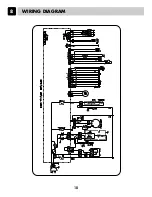

Page 18: ...WIRING DIAGRAM 8 18 ...

Page 20: ...TROUBLESHOOTING 9 20 ...

Page 21: ...Error Mode TROUBLESHOOTING 9 21 ...

Page 55: ...AUGUST 2011 PRINTED IN KOREA P No 3828EL9001Y ...