5-7

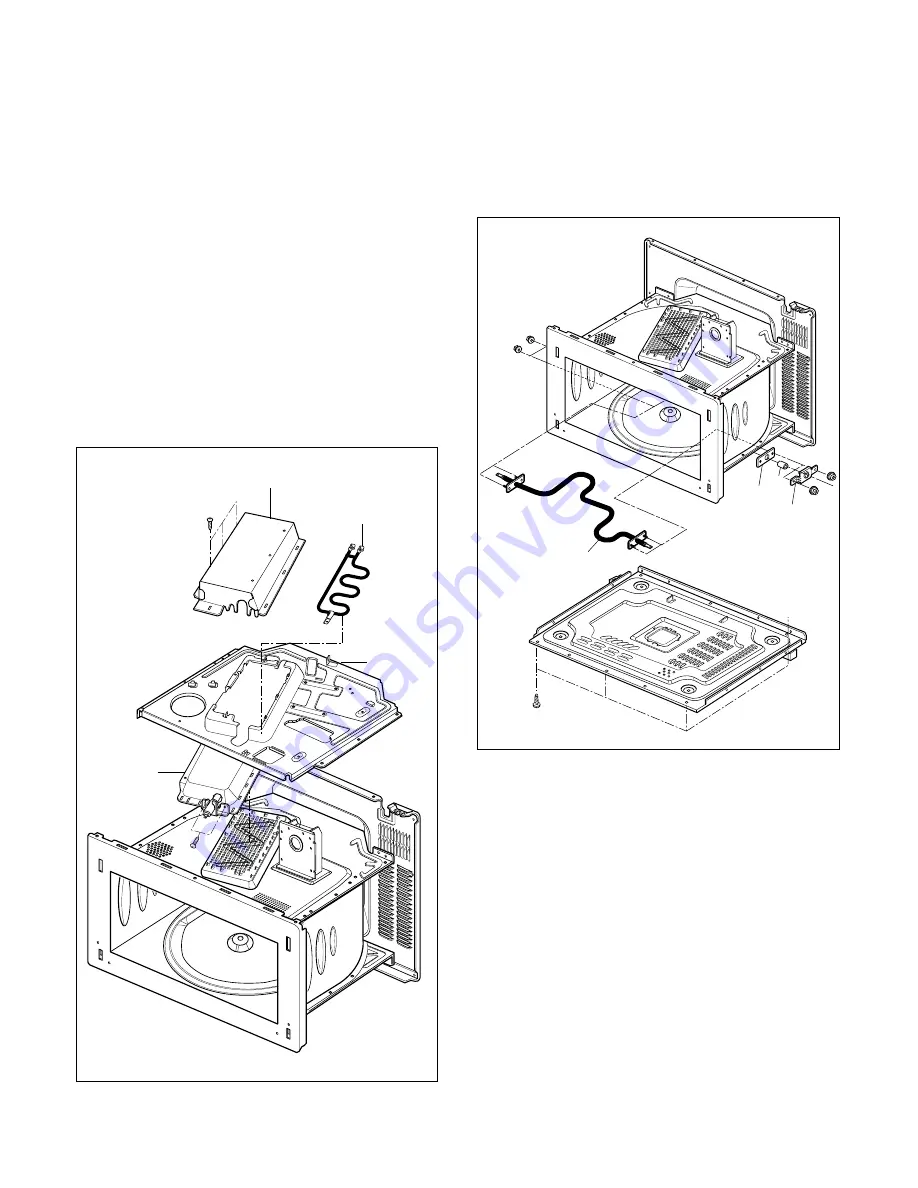

M. UPPER SHEATH HEATER REMOVAL

1) Remove two hex nuts holding the sheath heater.

2) Remove the sheath heater from the oven cavity.

N. UPPER HALOGEN HEATER REMOVAL

• If there are broken glass pieces between the

reflector and the oven cavity.

1) Remove the magnetron, air tunnel and fan motor

assembly.

2) Remove the latch boards and air tunnel - L/R.

3) Remove two screws holding the insulator - U to the

back plate and lift it up.

4) Remove the heater holder.

5) Remove the reflector and glass pieces.

• If the hologen heater isn’t broken.

1) Remove the heater holder and halogen heater.

O. LOWER HEATER REMOVAL

1) Disconnect the leadwire from the sheath heater.

2) Remove the base plate from cavity.

3) Remove the nuts from the oven cavity of the side.

4) Remove the gasket, ring and heater bracket.

5) Remove the sheath heater in the oven cavity.

Chamber-U

Air-Tunnel-U

Upper Sheath Heater

Insulator-U

Lower Sheath Heater

Gasket

Ring

Heater Bracket

Summary of Contents for SolarDOM MP-9485S

Page 9: ...SCHEMATIC DIAGRAM 4 3 ...

Page 37: ... 41 ...