Chapter 3 – Function Setting

48

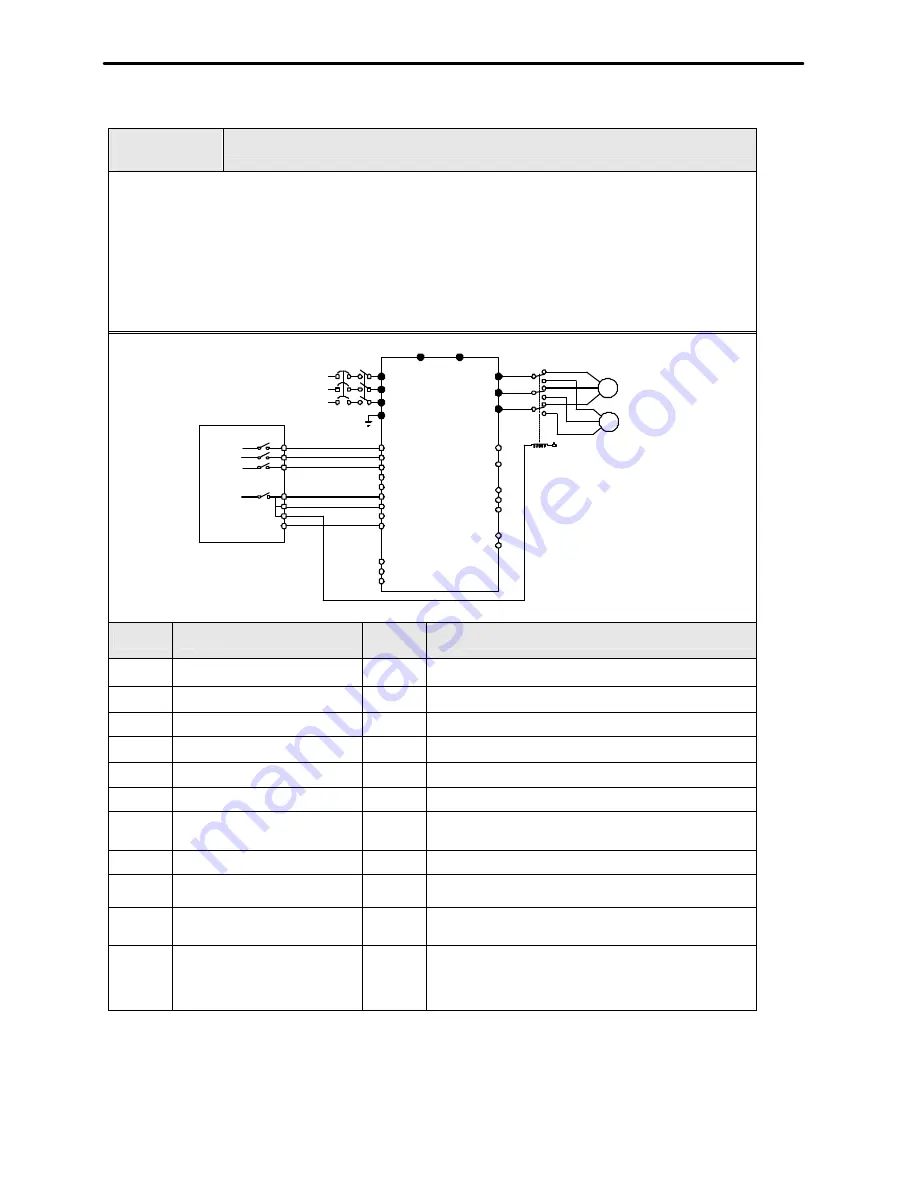

Operation

Example (3)

2

nd

motor operation

[Operation condition]

-. Control mode: V/F control

-. 1

st

motor + 2

nd

motor Operation by exchange using [2

nd

Func] (Values can be set differently)

-. Frequency command: Using Multi-step operation

(1

st

motor --- 50[Hz] as main speed, 2

nd

motor --- 20[Hz] with P1 terminal set as multi- step operation)

-. Accel/Decel time: 1

st

motor --- Accel time: 15[Sec], Decel time: 25 [Sec]

2

nd

motor --- Accel time: 30[Sec], Decel time: 40 [Sec]

-. Drive mode: Run/Stop via FX/RX

[Wiring]

R

S

T

G

U

V

W

B1

B2

FX

RX

BX

RST

JOG

P1

P2

P3

CM

VR

V1

5G

FM

5G

30A

30C

30B

AXA

AXC

IM 1st motor

3P

AC

input

IM

2nd

motor

1st /2nd motor

Switch-over

FX

RX

BX

CM

1st / 2nd

motor

select

Step

Parameter setting

Code

Description

1

Control Mode Selection

FU2-39 Set it to 0 {V/F}.

2

Drive mode

DRV-3

Set it to Fx/Rx-1.

3

Frequency Mode setting

DRV-4

Set it to 0 {keypad-1}. 1

st

motor freq setting

4

Multi-function input terminal P2

I/O-13

Set P2 to 2nd Func.

5

Multi-function input terminal P1

I/O-12

Set P1 to Speed-L. 2

nd

motor freq setting

6

Freq setting for 1

st

motor

DRV-0

Set it to 50[Hz].

7

Accel/Decel time setting for 1

st

motor

DRV-1,

DRV-2

Set Accel/Decel time to 15[sec]/25[sec].

8

Freq setting for 2

nd

motor

DRV-5

Set it to 10[Hz].

9

Accel/Decel time setting for 2

nd

motor

FU2-81/82 Set Accel/Decel time to 30[sec]/50[sec].

10

1

st

motor operation

Set it as main motor by turning P1, P2, output relay OFF.

Run the motor in FWD/REV direction using FX/RX terminal.

11

2

nd

motor operation

Set 2

nd

motor parameters by turning terminal P2 ON.

Change the freq setting to 20[Hz] by turning terminal P1 ON.

Change 2

nd

motor terminal by turning output relay ON.

Run the motor in FWD/REV direction by terminal FX/RX.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 morek@morek.eu