13

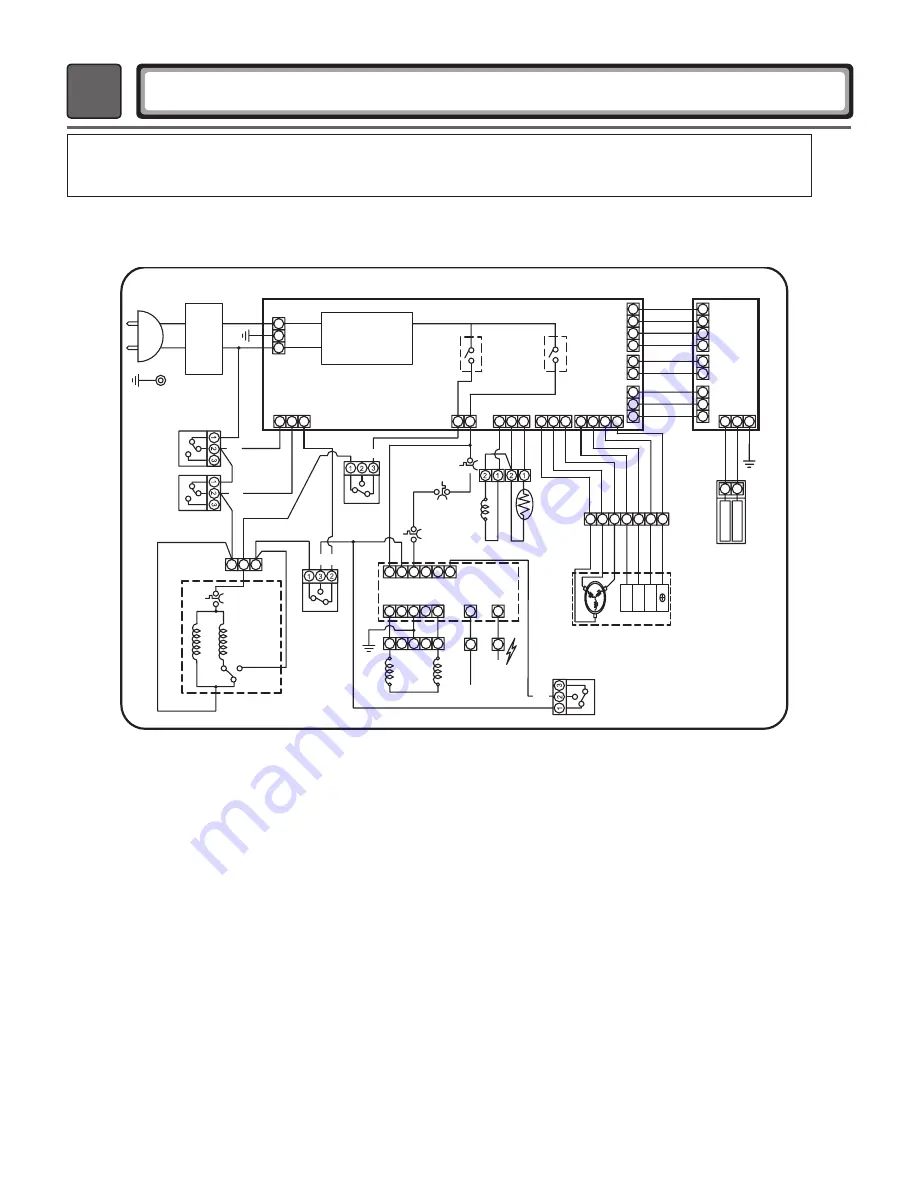

WIRING DIAGRAM

34

3 2

3

1

4

2

1

2

3

5

4

3

1

2

3

1

7

6

5

4

2

3

1

5

4

2

7

8

9

10

11

12

1

1

3

1

5

4

2

1

1

3 7 9

ELECTRONIC CONTROL

3

1

4

2

1

2

3

5

4

3

1

2 3

1

4

2

7 5 3

3

1

2

1 2

3

1

2

POWER

CORD

NOISE

FILTER

/

1

POWER CIRCUIT

MOTOR

RELAY

HEATER

RELAY

DOOR

SWITCH

LINT

FILTER

SWITCH

BELT

SWITCH

AIR FLOW

SWITCH

CENTRIFUGA

L

SWIT

CH

OVERLOAD

PROTECTOR

RESET

SWITCH

VALVE1

VALVE2

SENSOR

SPARK

PLUG

LINEAR

VALVE

OUTLET

THERMISTOR

*THER. - THERMOSTAT

SAFETY

*THER.

Max 150

℃

HI-LIMIT

*THER.

Max 150

℃

BLOWER

*THER.

Max 150

℃

Ha

Hb

GND

MOISTURE

SENSOR

DRUM MOTOR

FAN MOTOR

IGNITION CONTROLLER

%0

%0

%0

%0

%0

%0

%0

%0

%0

%0

%0

%0

%0

%.

:+

%.

:+

%.

:+

:+

</

%.

%1

:+

5'

*<

:+

:+

%1

</

:+

%.

%.

%/

</

6%

</

25

%.

*<

:+

6%

%/

97

*<

5'

%.

:+

6%

%/

97

*<

5'

%.

:+

%.

*<

6%

:+

*<

6%

:+

5'

25

%/

MAIN PWB

SUB PWB

*1

*1

NC

NO

NC

NO

NC

NO

NC

NO

NC

NO

/

1

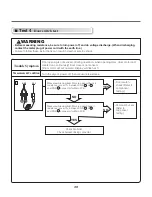

Caution : Label all wires prior to disconnection

when servicing controls. Wiring errors can

cause improper and dangerous operation.

Verify proper operation after servicing

CAUTION:

Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Verify proper Operation after

servicing.

GAS DRYER WIRING DIAGRAM

Summary of Contents for TCD1870CGG

Page 5: ...5 ...

Page 6: ...6 ...

Page 7: ...7 ...

Page 8: ...8 ...

Page 9: ...9 Gw G G G G G Gz G Gj G G G G G G G G G G UG G G G U ...

Page 14: ...14 4 INITIAL STEPS FOR INSTALLING YOUR DRYER ...

Page 18: ...18 z lwG GConnection of Gas Supply z lwG GElectrical Plug Connection ...

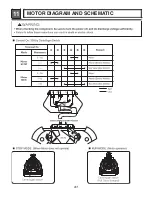

Page 31: ...31 11 MOTOR DIAGRAM AND SCHEMATIC ...

Page 32: ...12 CONTROL LAY OUT 32 PWB ASSEMBLY DISPLAY LAY OUT PWB ASSEMBLY LAY OUT ...

Page 33: ...33 PWB ASSEBMBLY SUB LAY OUT ...

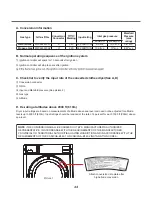

Page 36: ...36 Test 1 Thermistor Test Measure with Power Off ...