41

NO

YES

NO

YES

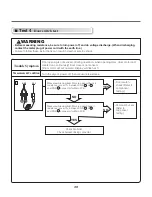

WARNING

•

Before doing maintenance. Be sure to turn power and gas off, and do voltage discharge.

•

Failure to follow these instructions can result in death or electric shock.

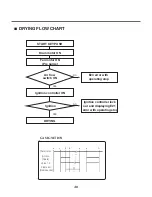

Trouble Symptom

Measurement Condition

Abnormal vibration and noise are occurred in the back side of the machine.

After turning power off, measure the resistance.

Is there abnormal vibration and noise

at the drum motor operation step on Test

mode?

Is there abnormal vibration and noise at the

fan and the drum motor operation step,

after pushing start button additionally?

Check legs which is well installed or not.

•

Check supply

Voltage, the drum

motor and the

roller.

•

Check blower fan

In the back side

and clean it.

Drum motor

Roller

Blower fan

Test 6

Blower fan abnormal vibration & noise solution

Summary of Contents for TCD1870CGG

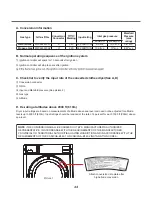

Page 5: ...5 ...

Page 6: ...6 ...

Page 7: ...7 ...

Page 8: ...8 ...

Page 9: ...9 Gw G G G G G Gz G Gj G G G G G G G G G G UG G G G U ...

Page 14: ...14 4 INITIAL STEPS FOR INSTALLING YOUR DRYER ...

Page 18: ...18 z lwG GConnection of Gas Supply z lwG GElectrical Plug Connection ...

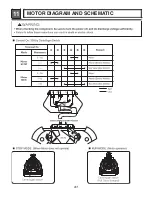

Page 31: ...31 11 MOTOR DIAGRAM AND SCHEMATIC ...

Page 32: ...12 CONTROL LAY OUT 32 PWB ASSEMBLY DISPLAY LAY OUT PWB ASSEMBLY LAY OUT ...

Page 33: ...33 PWB ASSEBMBLY SUB LAY OUT ...

Page 36: ...36 Test 1 Thermistor Test Measure with Power Off ...