12

MAINTENANCE INSTRUCTIONS

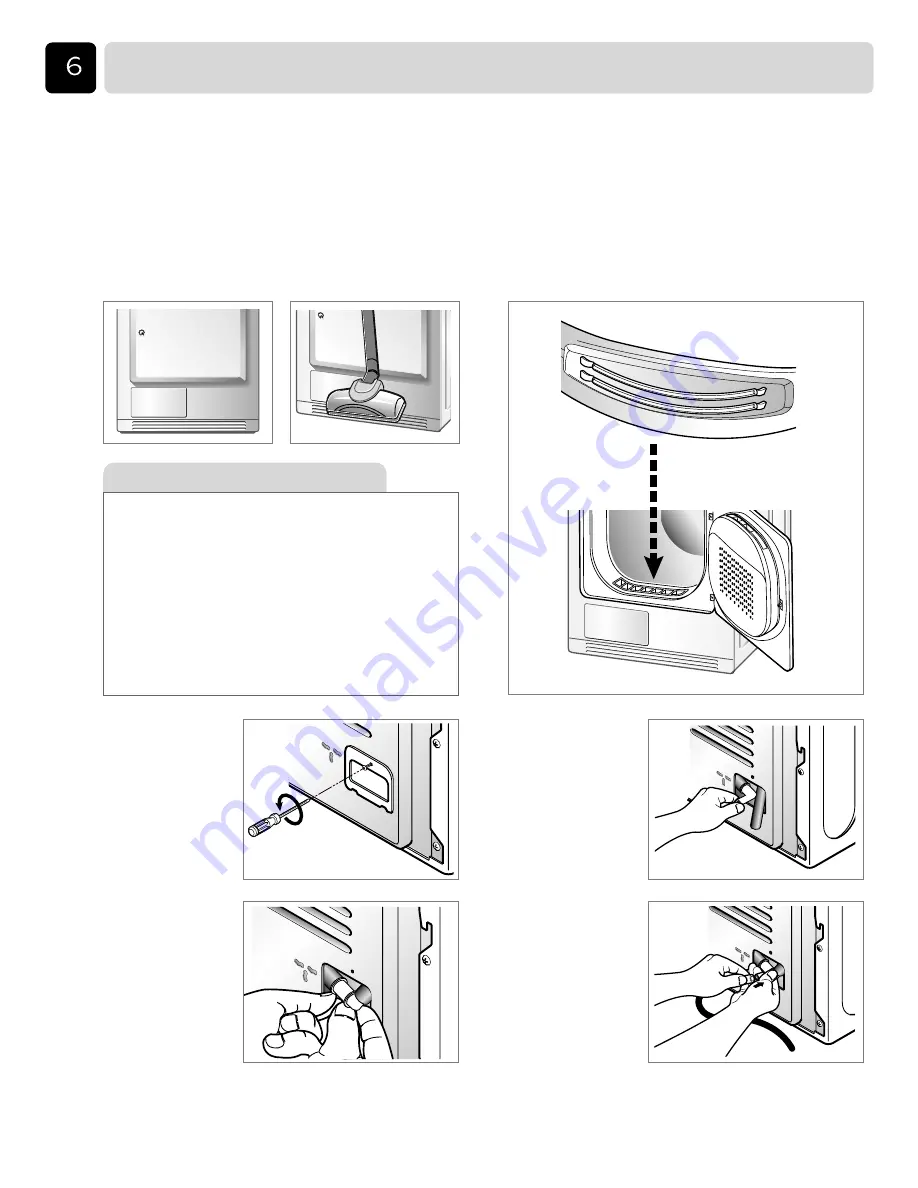

Front Ventilation Grille

Vacuum the front ventilation grill 3~4 time a year to

make sure there must be no build-up of lints or dirts

which cause improper intake air flow.

Moisture Sensor?

This device functions to sense the moisture

remaining contents of the laundry during operation

which means it must be cleaned all the time. The

main reason of cleaning this part is to remove the

build-up of lime scale on the surface of sensor. Wipe

the sensors inside drum (Shown in the picture).

1. Unscrew

cover.

2. Take

connecting kit

out.

3. Separate water

container hose

from the kit.

4. Connect drain

hose to the kit.

Condensed water Drain-out

Normally, condensed water is pumped up to water

container where water is collected until emptied.

Not only using water container, but water can be drained

out directly to drain hose especially when dryer is stacked

on top of washing machine.

With connecting kit for drain hose, you can simply change

water path and water reroute to the drainage facility.

Please follow the below steps.