System Set-Up

Installation Manual

85

ENGLISH

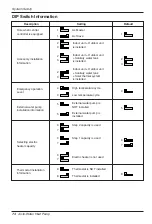

Temperature range setting

• Function Code 11

: Setting air temperature in cooling mode

Determine cooling setting temperature range when air temperature is selected as setting

temperature.

Only available when remote air temperature sensor is connected.

• Accessory PQRSTA0 should be installed.

• Also, Function Code 03 should be set properly.

• Function Code 12

: Setting leaving water temperature in cooling mode

Determine cooling setting temperature range when leaving water temperature is selected as

setting temperature.

Water condensation on the floor

• While cooling operation, it is very important to keep leaving water temperature higher than 16

°C. Otherwise, dew condensation can be occurred on the floor.

• If floor is in humid environment, do not set leaving water temperature below 18 °C.

Water condensation on the radiator

• While cooling operation, cold water may not flow to the radiator. If cold water enters to the

radiator, dew generation on the surface of the radiator can be occurred.

NOTICE

NOTICE

NOTICE

• Function Code 14

: Setting leaving water temperature in heating mode

Determine heating setting temperature range when leaving water temperature is selected as

setting temperature.

• Function Code 15

: Setting sanitary tank leaving water temperature

Determine heating setting temperature range of water tank leaving water.

Only available when sanitary water tank feature is installed.

• Sanitary water tank and sanitary water tank kit should be installed.

• DIP switch No. 2 and 3 should be set properly.

• Function Code 18

: Screed drying mode.

After installing water pipes for under floor heating, user can select screed drying mode for curing the

cement.

• Function Code 13

: Setting air temperature in heating mode

Determine heating setting temperature range when air temperature is selected as setting

temperature.

Only available when remote air temperature sensor is connected.

• Accessory PQRSTA0 should be installed.

• Also, Function Code 03 should be set properly.

CAUTION

NOTICE

Summary of Contents for Therma V AHUW096A2

Page 97: ......