T: 0191 516 6554

•

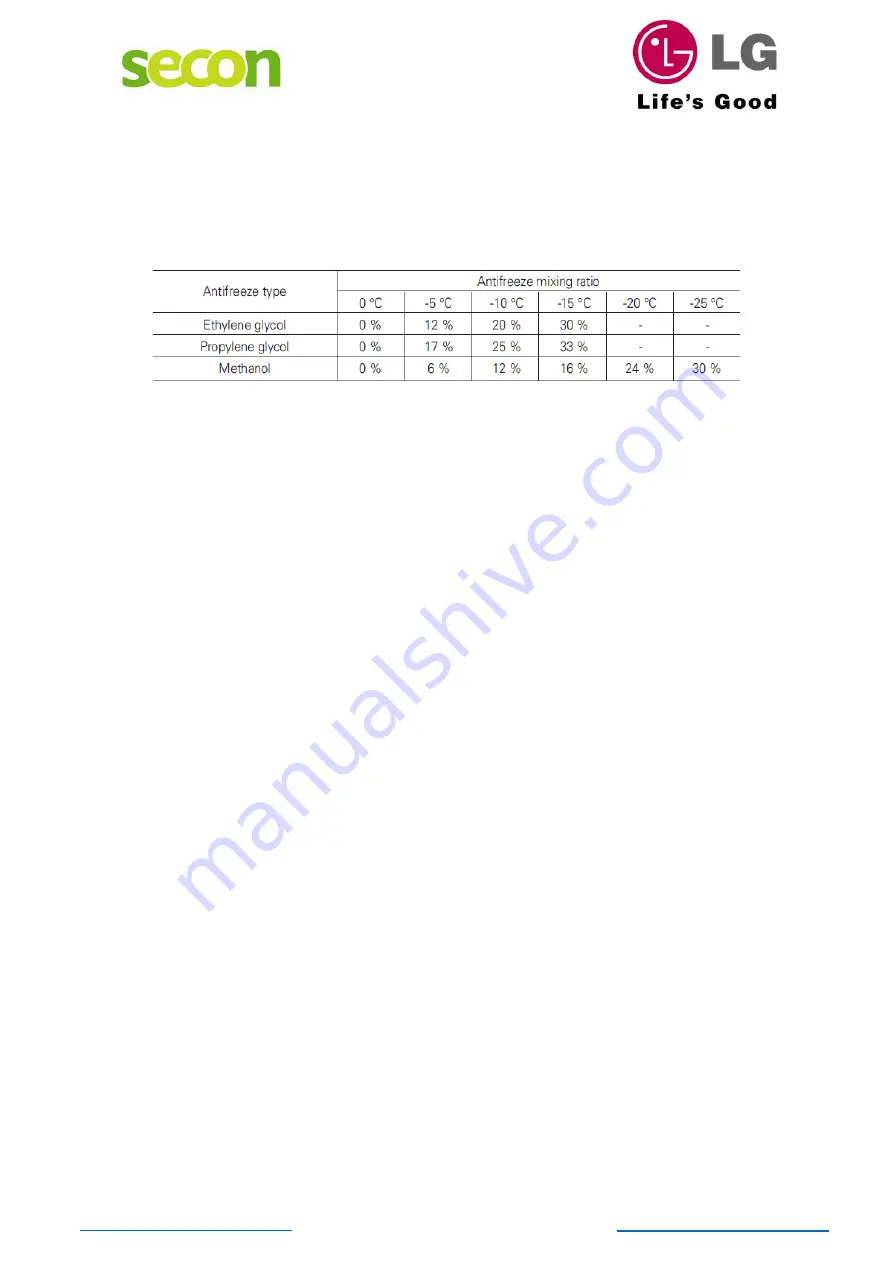

It is the responsibility of the installer to ensure the correct amount of antifreeze additive is applied to

the water system to protect the product against water temperatures below 0

℃

. The correct volume of

water contained in the system should be calculated, with six additional liters added for the AWHP

product, as per the installation instructions.

Guidance from this instruction is provided below :-

•

If Antifreeze is added to the hydraulic system water then the antifreeze solution temp can be adj usted in

the installer settings. (The setting is not visible normally, method is described later)

•

Possible settings are displayed as below.

-

Temperature : -5 / -10 / -15 / -20 / -25

℃

(Default : -5

℃

)

•

The values shown are not actual temperature setting but an offset that can be applied to the def ault value

of 0

℃

, as shown in the previous slide. When the function is activated the default valu e is -5

℃

.

•

Example if setting -10 is used;

-

entering water temp for judgment is reduced from 15

℃

to 5

℃

for protection starting

-

entering water for condition release is reduced from 18

℃

(15

℃

+ 3

℃

) to 8

℃

(5

℃

+ 3

℃

)

Pre-Start Check

Please check the following prior to starting the unit :

•

The power supply to the mono-bloc must have been on 6hr prior to starting.

•

Check all electrical and wiring connections are as per LG spec

•

Make sure that all hydraulic connection is as per LG spec

•

Make sure the system is full and vented.

•

Check the Anti-freeze level is adequate

•

Check that the system has been adequately flushed.

•

Check there is an adequately sized expansion vessel fitted to the system and safety relief valve. Inside the monobloc

there is a 8lt vessel with a 1 bar precharge, this is adequate for system volumes up to 230lt dependent on system

head.