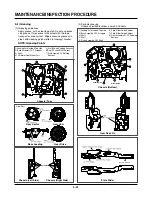

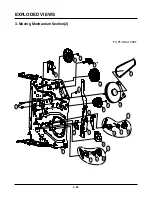

MAINTENANCE/INSPECTION PROCEDURE

4-21

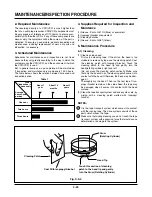

5-2) Greasing

(1) Greasing guidelines

Apply grease, with a cleaning patch. Do not use exces-

sive grease. It may come into contact with the tape

transport or drive system. Wipe excessive grease and

clean with cleaning patch wetted in Isopropyl Alcohol.

(2) Periodic greasing

Grease specified locations every 5,000 hours.

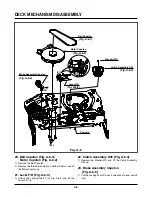

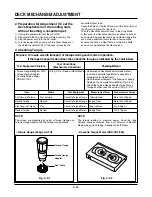

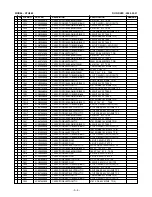

NOTE:Greasing Points

3

5

7

6

1

7

2

4

1) Loading Path Inside & Top side

2) Base Assembly P2, P3 stopper

3) Shaft

4) L/D Motor Gear Wheel Part

5) Arm Take-up Rubbing Sections

6)Reel S,T shaft(G381:Yellow)

7) Arm Assembly F/L Rotating

Sections

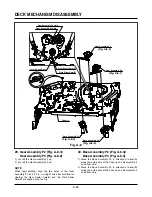

Guide Rail

Base Loading

Gear Drive

Gear Sector

Gear Cam

Gear Part

Chassis (Left Side)

Chassis (Right Side)

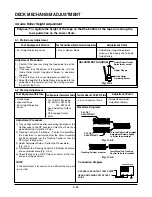

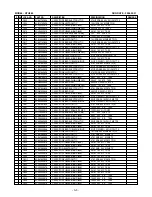

5

7

8

1

2

6

4

3

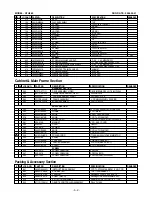

Slider Guide

Slider Guide

1) Loading Path Inside & Top side

2) Base Assembly P2,P3 stopper

3) Shaft

4) Shaft

5) Clutch Assembly D35 Shaft

6) Plate Slider Guide Sections

7) Plate Slider Guide Sections

8) Gear Assembly P2, P2 Rubbing

Sections

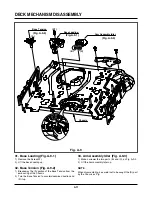

Chassis (Top)

Chassis (Bottom)

Gear Rack F/L

Plate Slider

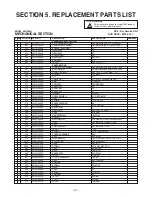

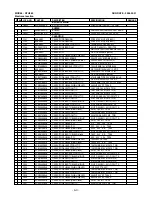

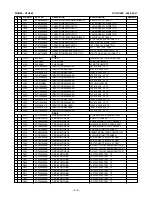

Summary of Contents for TL-AT130M

Page 23: ...3 14 3 13 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 1 OVERALL WIRING DIAGRAM ...

Page 24: ...3 16 3 15 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 2 POWER BLOCK DIAGRAM ...

Page 25: ...3 18 3 17 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 3 POWER CLRCUIT DIAGRAM ...

Page 26: ...3 19 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 4 AUDIO BLOCK DIAGRAM ...

Page 27: ...3 20 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 5 Y C BLOCK DIAGRAM ...

Page 28: ...3 22 3 21 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 6 A V CIRCUIT DIAGRAM ...

Page 29: ...3 23 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS ...

Page 30: ...3 25 3 24 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 7 SYSTEM BLOCK DIAGRAM ...

Page 31: ...3 26 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS ...

Page 32: ...3 28 3 27 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 8 SYSTEM CLRCUIT DIAGRAM ...

Page 33: ...3 30 3 29 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 9 JACK CLRCUIT DIAGRAM ...

Page 34: ...3 32 3 31 SECTION3 ELECTRICAL BLOCK CIRCUIT DIAGRAMS 10 KEY BOARD CLRCUIT DIAGRAM ...

Page 35: ...3 34 3 33 SECTION3 ELECTRICAL PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD ...