19

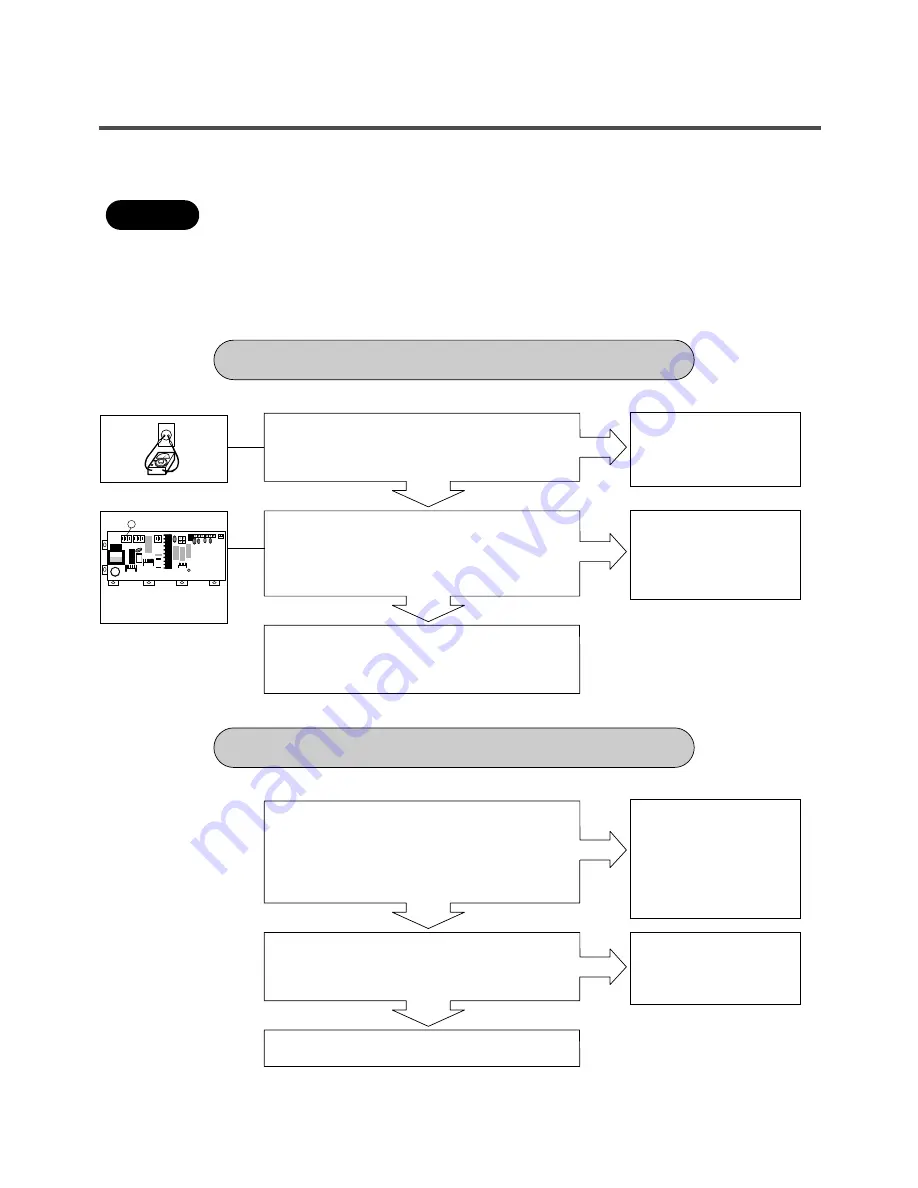

8-2.FAULT DIAGNOSIS AND TROUBLESHOOTING

1. Be careful of electric shock or disconnecting the parts while troubleshooting.

2. First of all, check the connection of each part terminal with wiring diagram.

3. If you replace the PWB assembly (Main), put in the connectors correctly.

CAUTION

NO

NO

YES

YES

PWB ASSEMBLY

NO

NO

YES

YES

1

Check the fuse?

Check the harness

Assembly.

Cancle the

Child-Lock by

pressing [Temp.] and

[Option]

simultaneously for 3

seconds.

Normal

When measuring the voltage of the outlet,

is the voltage AC 220-240V?

When measuring the voltage of White(3pin)

connector of the PWB assy, is the voltage

AC 220-240V?

Replace PWB assembly.

Does the Child-Lock is set?

First, unplug the power cord and plug again.

Check the buttons are operable.

Visit to check

NO POWER

ALL BUTTONS ARE INOPERABLE EXCEPT POWER BUTTON