43

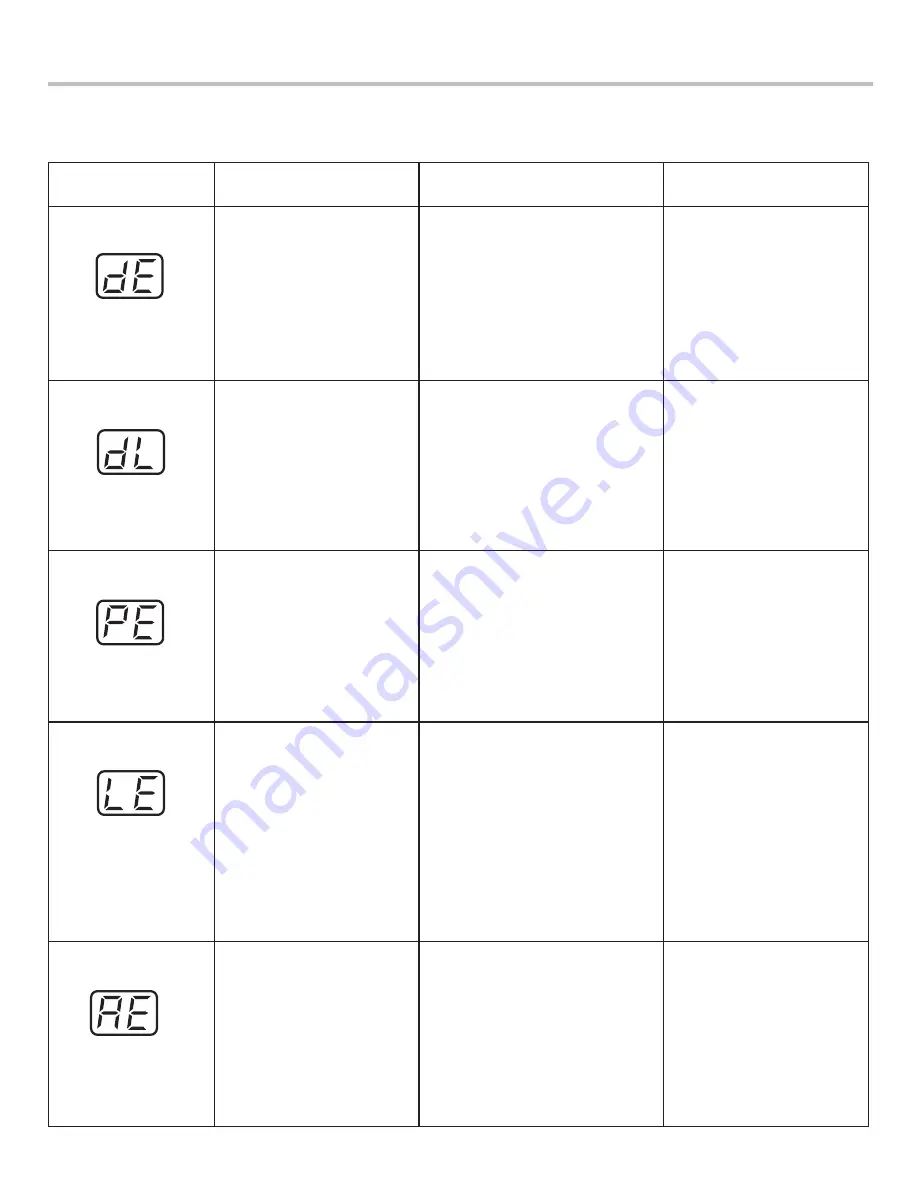

Display

Problem Diagnosis

Standard

Estimated Cause of

Abnormal Condition

Action

Lid open

(When the lid cannot

be locked)

•

When the door cannot be

locked

•

When the door cannot be

open

1. When there is a foreign object

in the lid lock hole

2. when lid lock unit is defect

3. When the connector connected

to the lid lock is fallen off or

contact is defect

4. When the hook is defect

5. When the lid is defect

6. When the controller is defect

•

Remove the foreign object

in the lid lock hole

•

Replace the lid lock

•

Reconnect the connector

or correct the contact

defect

•

Replace the lid

•

Replace the lid

•

Replace the controller

Lid locked

(When the lid cannot

be locked)

•

When the door cannot be

locked

•

When the door cannot be

open

1. When there is a foreign object in

the lid lock hole

2. When lid lock unit is defect

3. When the connector connected

to the lid lock is fallen off or

contact is defect

4. When the hook is defect

5. When the lid is defect

6. When the controller is defect

•

Remove the foreign object

in the lid lock hole

•

Replace the lid lock

•

Reconnect the connector

or correct the contact

defect

•

Replace the lid

•

Replace the lid

•

Replace the controller

Level sensor problem

(When there is a

problem with the level

sensor)

•

When the frequency

generated by recognizing

level height in the pressure

switch goes out of the

standard boundary (It occurs

when the condition of the

level frequency less than

20.0KHz or over 30.0KHz is

maintained for 5 sec. or more)

1. When the connector connected

to the pressure switch or the

blue 6 pin connector is fallen off

or contact is defect

2. When the pressure switch unit

is defect

3. When the controller id defect

•

Reconnect the connector

or correct the contact

defect

•

Replace pressures witch

•

Replace controller

•

Motor locking problem

(When there is a

problem with the motor)

•

When there is a problem

with the hole sensor

detecting the rotation of

the motor

•

It occurs when the motor is

locked

1. When the connector connected

to hole sensor or blue 4 pin

connector is fallen off or contact

is defect

2. When the hole sensor unit is

defect

3. When the controller is defect

4. When the motor connection

connector is fallen off or contact

is defect

5. When the bearing is locked

6. Hole sensor location defect

•

Reconnect the connector or

correct the contact defect

•

Replace hole sensor

•

Replace controller

•

Reconnect the connector or

correct the contact defect

•

Turn the inner tub with hand

to check the status, and if it

cannot be rotated, replace the

bearing housing assy.

•

Replace hole sensor

Clutch problem

(When there is a

problem in the clutch)

•

When the clutch is not

working

1. Connection part contact defect

2. Coupling damaged

3. Pulsator locked

•

Check the connection part

reconnection defect and

correct

•

Disassembly the Motor and

check the damage of the

coupling (If it is damaged,

replace the part)

•

Check the pulsator locking by

foreign object (Remove the

foreign object)

Summary of Contents for WF-S150S

Page 16: ...16 3 3 FUNCTION OF EACH BUTTON 1 For Pump Model WFS1959EKD 30 ...

Page 17: ...17 28 31 ...

Page 19: ...19 31 ...

Page 20: ...20 3 4 WASHING PROGRAMS ...

Page 21: ...21 ...

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...24 3 5 Other Functions Program or Course Program or Course Program or Course ...

Page 25: ...25 Program or Course Program or Course ...

Page 26: ...26 Program or Course Program or Course ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 30: ...30 Program or Course Program or Course ...

Page 31: ...31 ...

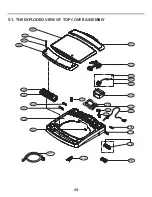

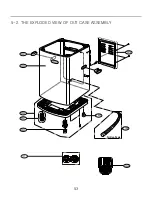

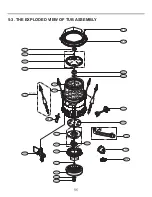

Page 54: ...54 5 EXPLODED VIEW TOP COVER ASSEMBLY CABINET ASSEMBLY TUB ASSEMBLY ...