15

14

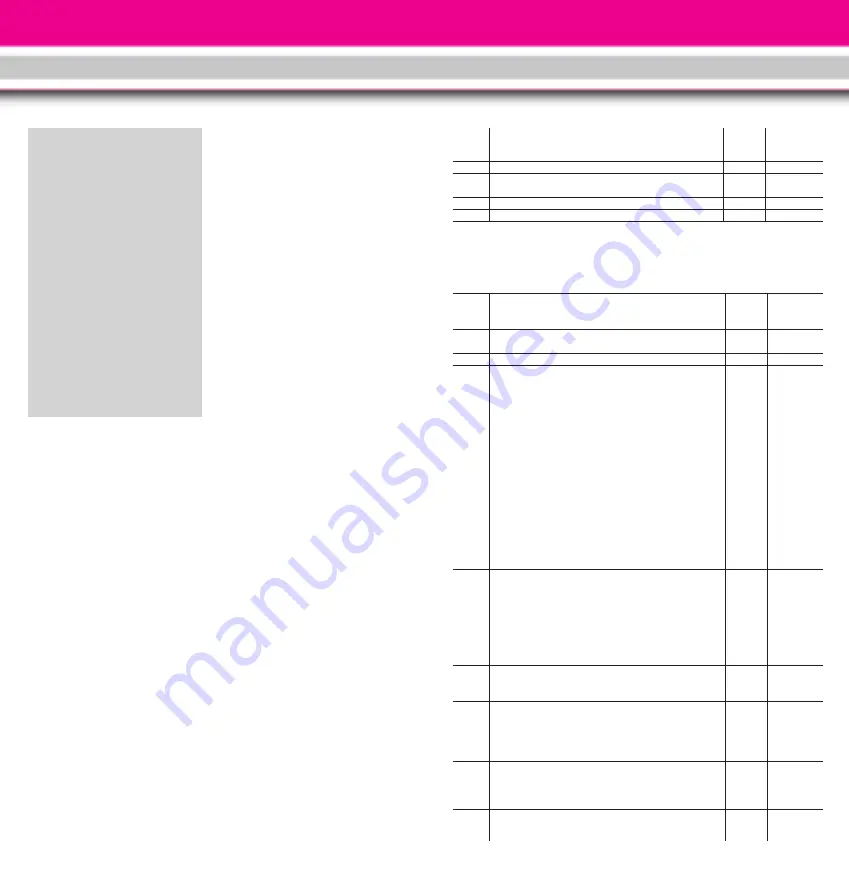

Maintenance parts

50010 Smoke and Cleaning Fluid

50019 Maintenance Oil

51020 Gear Lubricant

62201 Standard Motor with Short

Shaft

63120 Brushes, Assembled,

14 mm and

16 mm, 8 pieces (2 pack-

ages needed)

63218 Standard Pick-Up Shoes,

2 pieces

(2 packages needed)

68511 Plug-In Bulb, Clear, 5V,

10 pieces

68512 Plug-In Bulb, Red, 5V,

10 pieces

69104 Traction Tire, 37.5mm,

10 pieces

INSTRUCTIONS FOR ADVANCED

USERS

MTS Onboard Decoder

Programming functions

You can program numerous func-

tions of the onboard decoder to suit

your requirements. If you want to do

this, program the “function values”

in “registers” (CVs) using a PC and

the 55045 MTS PC Decoder

Programming Module. You can also

program the function values using a

55015 Universal Remote.

Hints:

- For normal operation, it is not nec-

essary to change the function val-

ues.

- If programming results in unsatis-

factory operation, you can repro-

gram the factory pre-set values of

most important CVs: Program reg-

ister CV55 to function value 55.

This also reprograms the loco

address to the factory pre-set

value.

To reprogram the factory pre-set

function values with the 55015 (dis-

plays shows “P --”) input 6, 5, and 5

and press the right arrow button. The

display shows “P --” again: Input 5,

5, and 5 and press the right arrow

button again.

You can program the following regis-

ters:

Register Function

Available Factory

values

pre-set

CV1

Loco address

(00..22)

[3]

CV2

Starting voltage

(0..255)

[0]

voltage for speed setting 1 - if loco starts only at a higher

speed setting, increase value.

CV3

Acceleration (1 = fast, 255 = slow)

(1..255)

[3]

CV4

Braking (1 = fast, 255 = slow)

(1..255)

[3]

Hint:

When programming with the 55015 Universal Remote,

the following CVs are programmed by input of the number of

the desired CV in CV6 and then input of the desired function

value in CV5 (see example below).

CV5

Max. voltage

(1..255)

[255]

Voltage for highest speed step - if a lower top speed is

desired, decrease value.

CV5

after input of CV6

function value for CV to be programmed

CV6

CV to be programmed

CV29

Configuration [4]

Normal direction:

4 = Analog and digital, factory-programmed speed steps

0 = Digital only, factory-programmed speed steps

20 = Analog and digital, user-programmed speed steps

16 = Digital only, user-programmed speed steps

Reversed direction:

5 = Analog and digital, factory-programmed speed steps

1 = Digital only, factory-programmed speed steps

21 = Analog and digital, user-programmed speed steps

17 = Digital only, user-programmed speed steps

With "Analog and digital:”

- Loco can operate on analog and digital layouts

With “Digital Only:”

- Normal operation on digital layouts.

- Operation on analog layouts not possible.

CV54

Hand-off function and “Back-EMF”

(0..3)

[2]

0 = hand-off function off, Back-EMF off

1 = hand-off function on, Back-EMF off

2 = hand-off function off, Back-EMF on

3 = hand-off function on, Back-EMF on

Hand-off function on: When operating with 55015, you can

adjust direction and speed for two seconds after selecting

a moving loco without causing the loco to stop.

CV55

Reset of most programmed CVs

55 = most important CVs are reset to the factory pre-set

values

CV60

Back-EMF: Max. adjustment factor (0: small, 255: large)

(1..255)

[48]

Specifies the max. increase or decrease of voltage applied

during each time interval (programmed in CV61)

Attention!

The factory pre-set values of CV60 and CV61

are optimized for LGB motors.

CV61

Back-EMF: Adjustment frequency (0: often, 255: seldom)

(0..255)

[0]

Specifies how often per second the motor voltage is

adjusted - accordingly, the loco will react to curves and

grades immediately or with a short delay

CV62

Back-EMF: Max. Adjustment (0: small, 255: max.)

(0..255)

[255]

Limits the total adjustment in motor voltage. If there is a