Maintenance Manual of Elevating Work Platform

24

⑩

Raise the platform to the highest location

and continue to press the lifting function

selector button.

Result: The alarm is outputted.

Result: No alarm is outputted. Calibrate the

platform overload system

5) Lower the platform via the manual lowering

function until the platform is folded

6) Carefully remove the short circuit lines of the

upper limit switch

7) Raise the platform to the highest location and

continue to press the lifting function selector

button.

Result: No alarm is outputted. The system

function is normal.

Result: The alarm is outputted and the

platform overload system is abnormal.

Eliminate the failures of limit switch, its wire,

installation bracket and the like or calibrate the

overload system.

8) Lower the platform to a given height above

the ground. The height of every model is

given in the following table

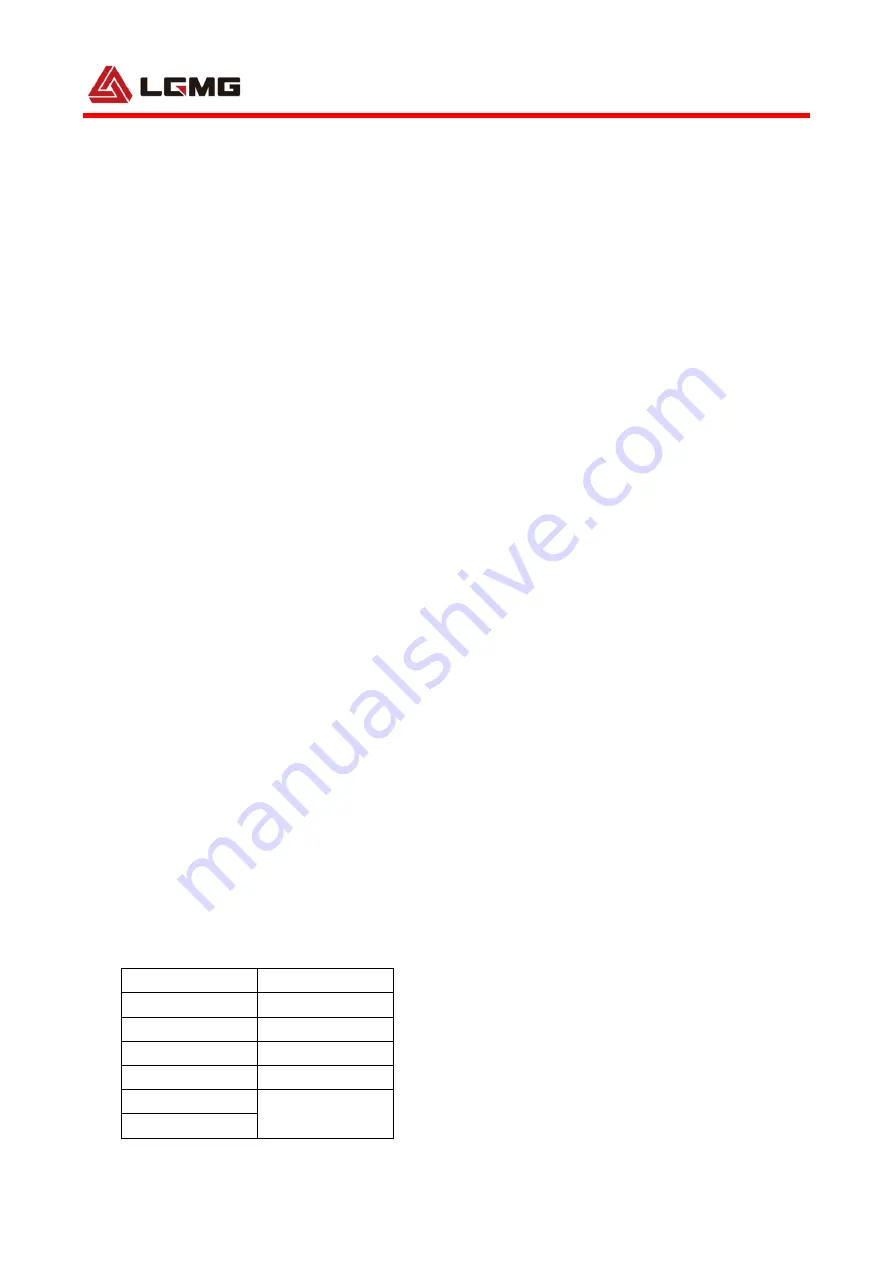

Model

Height (m)

SS0407E

1.8

AS0607E

2.5

AS0812E

3.2

AS1012E

3.73

AS1212E

4

AS1413E

9) Lift the safety prop, move it to the center of

the scissor sleeve center and rotate it upward

until it is vertical.

10) Lower the platform height until the safety

prop completely contacts the shaft sleeve

△

!

Warning: crush hazard

Be sure to put your hand on correct

position of the safety prop when

lowering the platform

.

11) Connect the wire of limit switch to its original

status and install the limit switch cover

12) Install the limit switch base cover.

13) Install the platform limit switch base cover.

14) Slightly raise the platform and recover the

safety prop to the installation position.

15) Lower the platform to the folding position

C-2

Replacement of exhaust cover of hydraulic oil

tank

This step shall be made once per 50h or per

season, whichever is shorter.

1)

The hydraulic oil tank is a ventilated oil tank.

An air filter is provided inside the exhaust

cover, which can be blocked as time goes on.

In case the exhaust cover fails or is

inappropriate installed, once any impurities

invade into the hydraulic system, the

component may be damaged. The frequent

inspection is the must for the poor working

Summary of Contents for AS0607E

Page 6: ...Maintenance Manual of Elevating Work Platform 1 Chapter 1 Maintenance...

Page 7: ...Maintenance Manual of Elevating Work Platform 2...

Page 33: ...Maintenance Manual of Elevating Work Platform 28...

Page 34: ...Maintenance Manual of Elevating Work Platform 29 Chapter 2 Appendix...

Page 35: ...Maintenance Manual of Elevating Work Platform 30...

Page 36: ...Maintenance Manual of Elevating Work Platform 31 2 1Battery Maintenance Schedule...

Page 41: ...Maintenance Manual of Elevating Work Platform 36 SS0407E SS0507E HYDRAULIC SCHEMATIC...

Page 42: ...Maintenance Manual of Elevating Work Platform 37 AS0607E HYDRAULIC SCHEMATIC...

Page 43: ...Maintenance Manual of Elevating Work Platform 38 AS0812E HYDRAULIC SCHEMATIC...

Page 44: ...Maintenance Manual of Elevating Work Platform 39 AS1012E AS1212E HYDRAULIC SCHEMATIC...

Page 45: ...Maintenance Manual of Elevating Work Platform 40 AS1413E HYDRAULIC SCHEMATIC...

Page 46: ...Maintenance Manual of Elevating Work Platform 41 SS07E ELECTRIC SCHEMATIC...

Page 47: ...Maintenance Manual of Elevating Work Platform 42 AS07E AS08E AS12E ELECTRIC SCHEMATIC...

Page 48: ...Maintenance Manual of Elevating Work Platform 43 AS1413E ELECTRIC SCHEMATIC...