MT86H

Operation

and

Maintenance

Manual

69

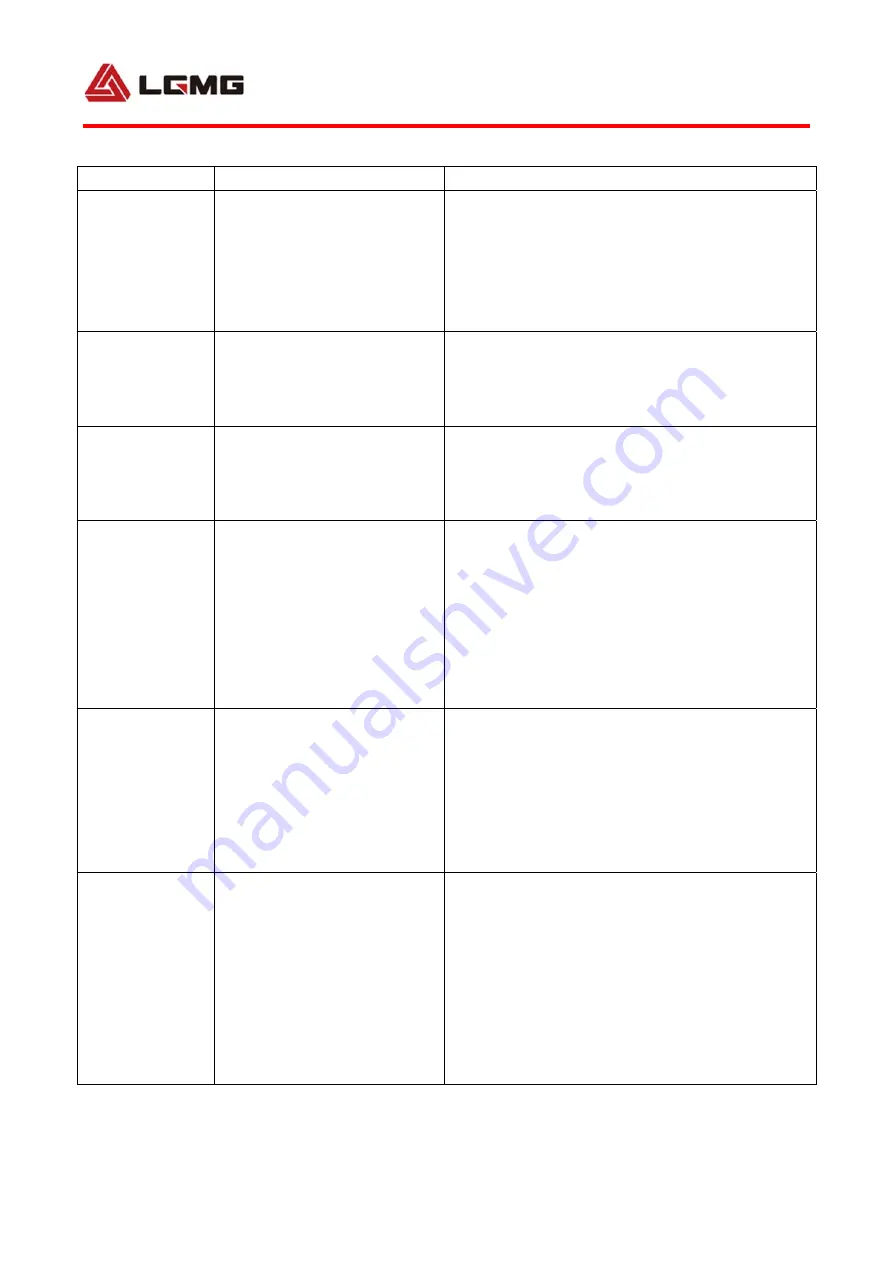

Fault

Causes

Solutions

Shift

is

difficult

or

is

unavailable

after

the

clutch

has

been

changed

The

cap

assembly

drops

during

assembly

so

that

the

return

spring

is

twisted;

The

spring

(with

scratch

on

the

drive

disc)

is

damaged

by

tool

during

assembling

Do

not

use

the

cover

assembly

that

has

ever

dropped;

Check

the

return

spring

carefully

before

assembling;

Do

not

try

to

insert

the

drive

disc

to

stop

the

engine

with

a

tool

while

the

engine

is

running

Shift

is

difficult

or

is

unavailable

after

the

clutch

is

renewed

The

clutch

cover

is

not

accurately

positioned;

Bolt

tightening

sequence

is

not

proper

Check

the

positioning

before

assembling;

Tighten

bolts

in

proper

sequence

(diagonally)

Pedal

jitters

at

disengaging

The

transmission

input

shaft

interferes

with

the

disengaging

lever

during

assembling

Accurately

guide

the

clutch

into

the

transmission

input

shaft

to

avoid

any

interference

during

assembling

It

is

difficult

to

depress

the

pedal

and

the

stiffness

increases

with

time.

The

pre

‐

load

of

the

release

bearing

is

too

small

or

it

is

not

preloaded;

The

preloaded

spring

is

not

installed

properly

or

the

self

‐

regulator

has

failed

Check

all

relevant

connections

thoroughly

during

the

clutch

assembling;

ensure

that

the

clutch

cable

operates

smoothly

throughout

operation

of

the

clutch;

check

the

self

‐

regulator;

always

refer

to

the

installation

manual

of

the

manufacturer

for

proper

regulation;

keep

the

preload

between

minimum

50N

and

maximum

80N

The

noise

associated

with

the

engine

occurs

when

the

pedal

is

depressed

to

the

bottom

The

clutch

regulation

is

improper

or

the

self

‐

regulator

has

failed

Check

the

cable,

related

connections

and

self

‐

regulator

systematically,

and

always

refer

to

the

installation

manual

of

the

manufactuter

for

proper

regulation

The

stiffness

at

a

certain

point

in

the

pedal

travel

is

large,

the

transmission

generates

noise,

the

clutch

vibrates,

and

the

pedal

jitters

The

guide

sleeve

of

the

release

bearing

is

worn;

The

fork

deforms

Check

the

fork,

or

replace

it

if

necessary;

Replace

the

guide

sleeve

of

the

release

bearing

if

any

wear

sign;

Make

sure

the

parts

are

lubricated

Summary of Contents for MT86H

Page 9: ...MT86H Operation and Maintenance Manual 1 Chapter I Safety ...

Page 10: ...MT86H Operation and Maintenance Manual 2 ...

Page 18: ...MT86H Operation and Maintenance Manual 10 ...

Page 19: ...MT86H Operation and Maintenance Manual 11 Chapter II Product Introduction ...

Page 20: ...MT86H Operation and Maintenance Manual 12 ...

Page 25: ...MT86H Operation and Maintenance Manual 17 Chapter III Operation ...

Page 26: ...MT86H Operation and Maintenance Manual 18 ...

Page 64: ...MT86H Operation and Maintenance Manual 56 ...

Page 142: ...MT86H Operation and Maintenance Manual 134 ...

Page 143: ...MT86H Operation and Maintenance Manual 135 Chapter V Maintenance ...

Page 144: ...MT86H Operation and Maintenance Manual 136 ...

Page 160: ...MT86H Operation and Maintenance Manual 152 3 Lubrication diagram ...

Page 161: ...MT86H Operation and Maintenance Manual 153 Chapter VI Annex ...

Page 165: ...157 6 5 Schematic diagram of electrical system ...