Section 3

3-20

Operation

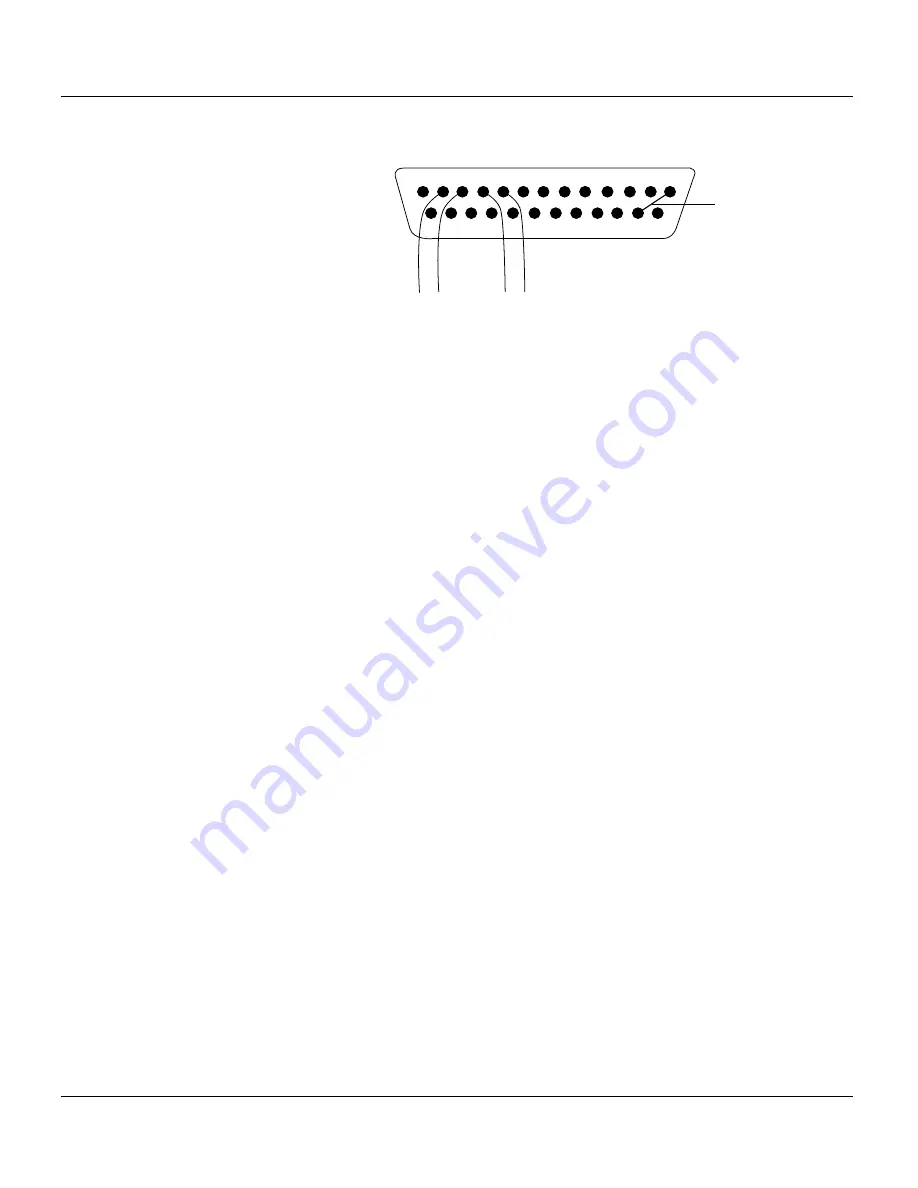

25-pin RS-232C Port

13 12 11 10 9

8

7

6

5

4

3

2

1

25 24 23 22 21 20 19 18 17 16 15 14

Jumper

610-03

black

red

black

red

LI-610

Figure 3-3. Connection of the 610-03 and LI-610 to the LI-6200 25-pin

RS-232C port (shown connected to spare input channels 1 and 2).

References

Buck, A.L. 1981. New equations for computing vapor pressure and

enhancement factor. J. Appl. Meteor. 20: 1527-1532.

Goff, J.A., and S. Gratch. 1946. Trans. Amer. Soc. Heat. and Vent. Eng.,

Vol. 52, p. 95.

Hyland, R.W. 1975. A correlation for the second interaction virial

coefficients and enhancement factors for moist air. J. Natl. Bur. Stand.,

79A, 551-560.

LI-COR, inc. 1990. LI-6262 CO

2

/H

2

O Analyzer: Instruction Manual.

Publication No. 9003-59. LI-COR, inc.

List, R.J. 1966. Smithsonian Meteorological Tables, 6th rev. ed. The

Smithsonian Institution, 527 pp.

Lowe, P.R. 1977. An approximating polynomial for the computation of

saturation vapor pressure. J. Appl. Meteorol. 16:100-103.

McDermitt, D.K., 1990. Sources of error in the estimation of stomatal

conductance and transpiration from porometer data. HortScience 25(12):

1538-1548.

Wexler, A. 1976. Vapor pressure formulation for water in the range 0° to

100° C. J. Res. Natl. Bur. Stand., 80A, pp. 775 ff.