4617000L

Copyright © Liberty Pumps, Inc. 2019 All rights reserved.

5 | EN

Cords

LowPro systems come with two cords—one to the float switch and

the other to the pump motor. The float switch cord has a

piggyback (series) plug enabling the pump motor cord to be

plugged into the back of it. Both cords must be connected in

series for automatic operation.

The purpose of this design is to allow temporary manual

operation of the pump. For manual operation, or in the event of a

float switch failure, the pump cord can be separated and plugged

into the electrical outlet, directly bypassing the switch.

Use and Care

A routine of regular cleaning will keep the LowPro in good

working order. The exterior of the unit may be cleaned with a

damp cloth and normal household cleaners. Never spray or dump

water or chemicals directly on the unit.

Considerations

The LowPro41LP can be installed freestanding or built-in,

concealing the pump compartment and piping. The platform

section of the tank is sized to fit flush with an elevated floor

framed with 2" x 6" material.

Access to pump compartment

is required on built-in installations.

To accommodate future service, it is important to allow access to

the pump and switch cover when the unit is being framed-in with

a wall behind the water closet. This can be accomplished by

framing this portion of the tank into a closet, utility, or other

accessible room.

If installing walls or floor joists,

use caution to ensure that nails,

screws, or other sharp objects do not puncture the tank when

framing.

For addition of a sink or shower,

a rubber pipe seal is included

that accepts 2" schedule 40 PVC piping. Showers must be elevated

to allow gravity flow to unit.

If connecting a washing machine

, the preferred method is to

drain the washer into a tub sink with a lint sock prior to the

LowPro. This requires periodically removing the access cover to

clean lint and debris from the switch.

The tank installation location

must be level.

LowPro tank contains three

textured areas

acceptable

for installing rubber pipe

grommet.

Installation

outside of these areas

may result in damage to

internal components.

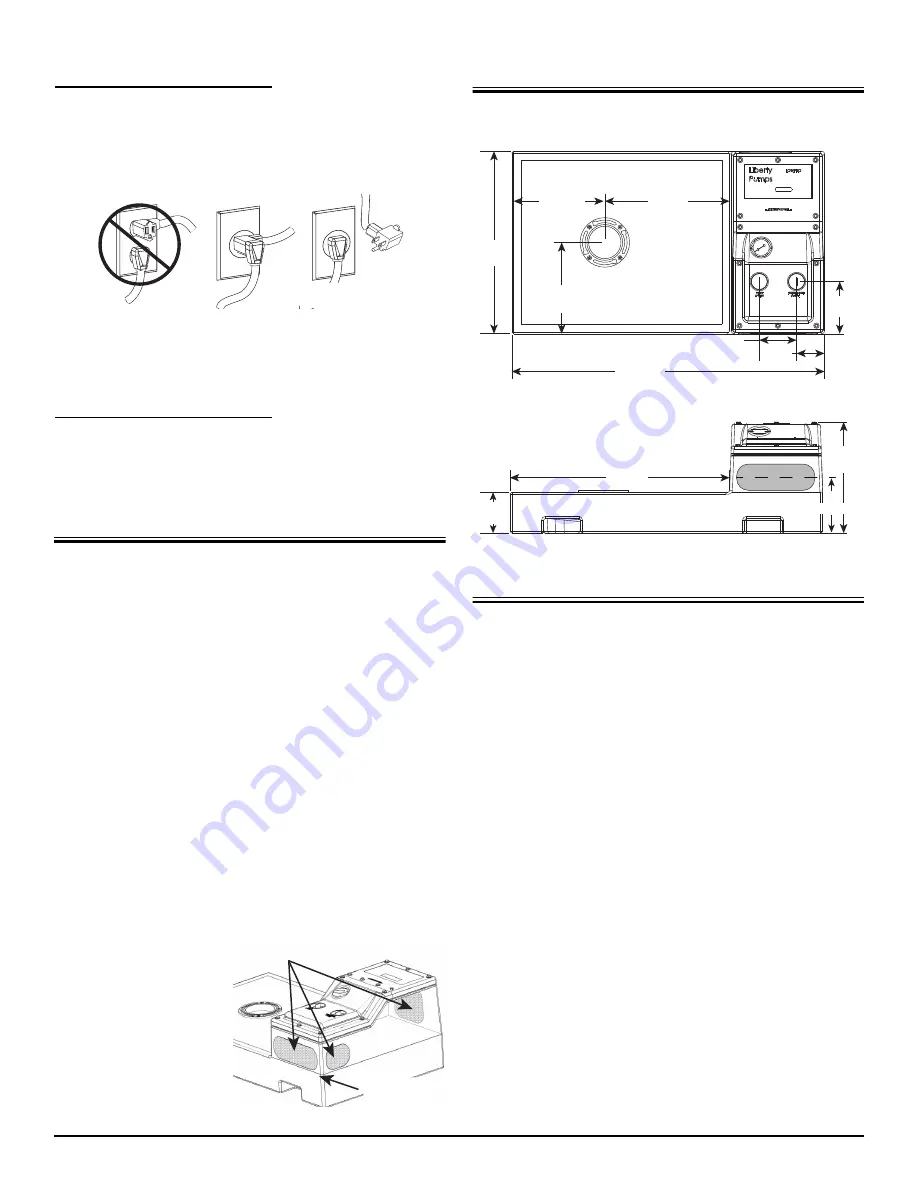

Dimensional Data

Installation

1.

Position the tank in its desired location and ensure that it is

level.

Use hydraulic cement or similar material for leveling the floor

if necessary.

2.

Determine the closest and most readily accessible locations

to tie in the discharge and vent lines to existing lines. Take the

necessary measurements and determine what plumbing

fittings and pipes are needed.

3.

An inlet for a 2" PVC drain line from additional fixtures (i.e.,

sink or shower) may be installed using the supplied rubber

pipe grommet.

Determine the best location for the drain line to enter the

tank—making sure it is within the marked textured areas of

the pump chamber.

Do not drill below or outside of the

textured areas.

Make sure drain lines have adequate gravity

flow to the system. If a shower is being used, elevate the

shower to allow for proper trapping and drainage.

4.

Drill a 3" diameter hole and insert the provided grommet.

Slide the 2" PVC drain line into the pipe grommet, lubricating

the pipe if necessary to ease installation.

5.

Install a 2" PVC pipe to the discharge connection on the

cover.

Threaded connections at tank require hand-tightening only.

Use thread seal tape to seal pipe threads.

Temporary Manual

Operation

YES!

NO!

Do Not Drill

Below This Line

Acceptable Rubber Pipe Grommet Locations

TOP VIEW

14-5/8”

[37 cm]

29-1/2”

[75 cm]

24-1/2”

[62 cm]

12-1/4”

[31 cm]

17”

[43 cm]

12-1/2”

[30.5 cm]

42”

[106.7 cm]

5”

[12.7 cm]

3-3/4”

[9.5 cm]

7”

[17.8 cm]

5-1/4”

[13.3 cm]

SIDE VIEW

7”

[17.8 cm]