6 | EN

Copyright © Liberty Pumps, Inc. 2019 All rights reserved.

4617000L

6.

Attach the 2” check valve to the discharge pipe as close to the

top of the tank as possible. Make sure that the arrow on the

check valve is pointing up, away from the pump.

Do not reduce the discharge pipe size below 2".

7.

Complete the discharge piping to the house waste line using

a minimum number of turns.

8.

Install a 2" vent pipe into the vent opening on the cover.

9.

Connect the vent pipe to the house vent line or directly to the

atmosphere. Unit must be vented in accordance with local

plumbing codes.

Do not use an air admittance valve or a mechanical

spring-loaded venting device.

10.

If installing a finished floor above the LowPro tank system,

continue with steps 11 through 13, otherwise, resume

installation at step 14.

11.

The rough opening size required for installation using

standard 2” x 6” floor joists will vary depending on the actual

installation and the orientation of the tank. The overall rough

opening size needed to enclose the entire LowPro tank is 42”

.

12.

Measure the finished flooring thickness and determine the

number of closet flange spacers needed to bring the closet

flange up to the finish floor.

13.

Set the proper number of plastic closet flange spacers onto

the brass closet flange.

The foam gasket material on the

spacer(s) must be facing down.

The spacer(s) will not be

secured to the closet flange, so use care not to move them

during the installation of the toilet.

14.

Install the provided wax toilet bowl seal ring onto the toilet

following the directions included with the toilet.

15.

Install the toilet onto the closet flange following the

directions included with the toilet.

16.

Hook up the water line to the toilet.

17.

Turn the water on and fill the toilet tank. Test for leaks. Flush

the toilet several times and allow the pump to cycle to ensure

proper operation.

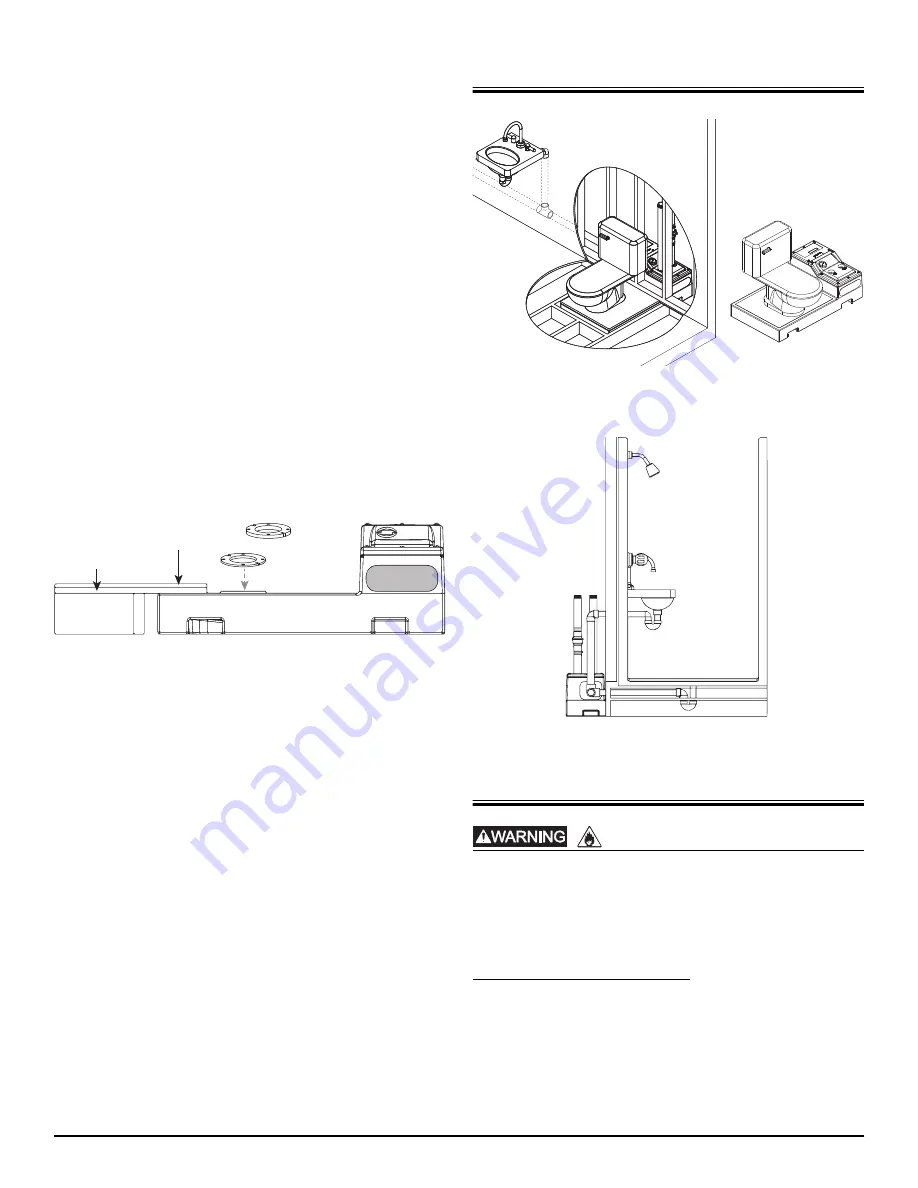

Sample Illustrations

Figure 1. Typical Finished Installation and

Optional Toilet Orientation

Figure 2. Elevated Shower Side View

Maintenance and Troubleshooting

Accidental contact with electrically live parts, items, fluid, or

water can cause serious injury or death.

Always disconnect the pump from power source before

attempting to service the pump. Fatal electrical shock could

occur.

Maintenance

The LowPro system requires no routine maintenance. The exterior

of the unit may be cleaned with a damp cloth and normal

household cleaners. Never spray or dump water or chemicals

directly on the unit.

If a washing machine is connected, periodically remove the access

cover to clean lint and debris from the float switch.

2 x 6 Floor Joist

LowPro Tank

Subfloor

(plywood, etc.)

Finish Flooring

(tile, linoleum, etc.)

Two supplied

(1/4” and 1/2”)

May be stacked for

total of 3/4”

Spacers

RISK OF FIRE