Mechanical Specifications

5 -- 4

Liebert HPC---S 006---022---PD---273571---01.03.2012

D

freecooling; 100% water flow through the freecooling coils and then through the evaporator, without

compressors operation.

Fan speed control, compressor starting and compressor partialisation are managed by the micropro-

cessor control with different strategies in order to increase the energy saving as much as possible.

Recirculating Pumps (Option)

All the models of the

Liebert HPC---S 006---022

series can be equipped with one

or two water circulating pumps, factory---piped.

On each

Liebert HPC---S 006---022

unit it is possible to select the pump

type and quantity (with high or low head), depending on the pressure

available from the applications. They are suitable for operation with wa-

ter---ethylene glycol mixture up to 35%---65% by weight and mixture tem-

peratures down to 4° C.

The pumps are of the close---coupled centrifugal type, with single im-

peller featuring axial suction and radial discharge, direct driven. The electrical

motor is asynchronous, with squirrel cage rotor, close construction, external ventil-

ation, and two poles, having IP 55 protection and Class F insulation. It is standard supplied with IE2 mo-

tors and compliant with Regolation (EC) no. 640/2009.

Pump body and impeller are in stainless steel or cast iron. Mechanical seal is in ceramic/carbon rings,

NBR elastomers, other parts are made of stainless steel. Mounting dimensions

are according to EN 12756 (ex DIM 24960) and ISO 3069.

O---ring are made of NBR.

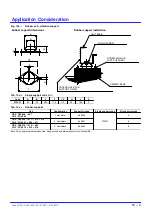

Easy maintenance with “back pull---out” design: it is not

required to disconnect the pump body from the pipe line,

due to back pull---out design.

Suction and discharge ports are threaded (Rp ISO 7) or

flanged according to EN 1092---2 (ex UNI 2236) and DIN

2532.

Microprocessor controls manage the pump rotation and

stand---by and automatically start the stand---by pump in case of

failure of the primary one.

Fan Section

Fans are axial type, with blades made of aluminium sheet insert, sprayed

with PP plastic statically and dynamically balanced, directly coupled to

an electric motor with external rotor. They are balanced G66,3 accord-

ing to DIN ISO 1940 part 1, have an IP54 degree of protection, Class

F winding insulation and internal thermalprotection. The characterist-

ics of the motor depend on the unit version:

”G”:

EC 6-pole motor, propeller diameter 900 mm,

. . . . . . .

900 rpm as standard, EC 8-pole motor, propeller

diameter 800 mm, 700 rpm as option;

”B” BASE:

AC (EC) 6-pole motor, propeller diameter 900 mm,

. .

900 rpm as standard, AC (EC) 6-pole motor, propeller

diameter 800 mm, 900 rpm as option.

The fans are complete with safety protection grilles and high efficiency nozzles.

Die cast aluminium blades with a sickle-shaped profile are used in order to improve the sound attenu-

ation effect.

Fan speed control is achieved - as standard - by means of a continuous fan speed regulator. This ensures

also to run the compressors always with optimum working efficiency.

EC Fans

In all versions, as standard or alternative to the modulating adjustment (TRIAC), it is possible to choose

fans with electronic switching motor, with the same aeraulic performance as those installed in the selec-

ted unit, as well as the possibility of a fan modulating adjustment entirely managed by the micropro-

Summary of Contents for HPC-S 006

Page 50: ......