Unpacking and Inspections

4

1.2.1 Handling Considerations

The STS2/PDU is bolted to a wood shipping pallet to allow handling by forklift equipment or a pallet

jack.

Check the unit size and weight. Refer to the cabinet drawings furnished with the unit for size and

weight. Typical cabinet dimensions are shown in

Figures 7

through

22

. Typical unit crated weights

are:

Plan the route. Review the route over which the unit will be transported to its installation location to

ensure that all passages are large enough to accommodate the unit and support the weight.

Check for any non-negotiable corners or offsets in hallways. Before moving the unit to the intended

location, review

2.0 - Location Considerations

.

1.2.2 Unit Preparation

The unit can be removed from the pallet before it is moved to its location.

Complete the following steps to properly remove the STS2/PDU from the shipping pallet:

1. Set the pallet in a level area with enough room to maneuver and remove the unit.

2. Remove the bolts holding the unit to the shipping pallet (located in the base of the unit).

3. Remove the shipping blocks from under the frame of the unit.

4. Use a forklift to raise the unit off the pallet and onto the floor. On the 250A unit ensure that the

forklift is clear of the unit's casters and leveling feet. Lift the unit from the rear.

5. Conduct an internal inspection of the unit. See the list in

1.3 - Internal Inspections

.

1.3

Internal Inspections

After the STS2/PDU has been unpacked, conduct an internal inspection:

1. Verify that all items have been received.

2. If spare parts were ordered, verify their arrival.

3. After the Static Transfer Switch 2 Power Distribution Unit has been removed from the pallet,

open the door and remove cabinet panels to check for shipping damage to internal components.

4. Check for loose connections or unsecured components in the cabinet(s).

5. Check for any unsafe condition that may be a potential safety hazard.

After the STS2/PDU has been inspected and no problems are found, the unit can be moved to its

installation location. If using a forklift, remember to lift the unit from the rear.

!

WARNING

Exercise extreme care when handling STS2/PDU cabinets to avoid equipment damage or

injury to personnel.

The cabinet can be safely tilted 15 degrees in any direction by forklift.

If moving the unit up a ramp on its casters (if the unit is so equipped) or a pallet jack, ensure

that the incline does not exceed 15 degrees.

Locate the center of gravity symbols and determine the unit’s weight

before handling

the cabinet.

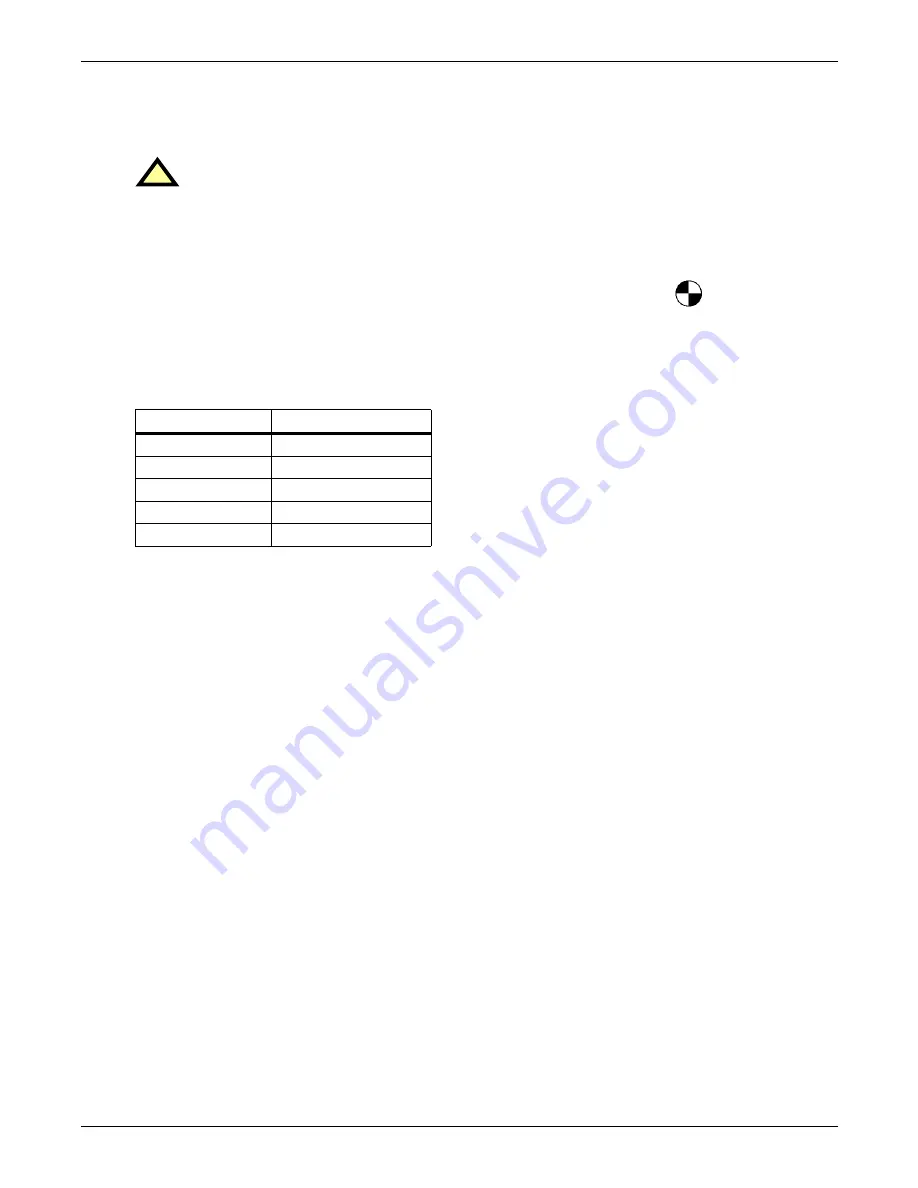

Table 1

Shipping weights (typical)

Model

Weight - lbs. (kg)

250A

3730 lbs. (1692 kg)

400A

4900 lbs. (2132 kg)

600A

5580 lbs. (2531 kg)

800A Module A*

4052 lbs. (1838 kg)

800A Module B*

4595 lbs. (2084 kg)

*800A ships on two separate pallets

Summary of Contents for PDUTM

Page 25: ...Installation Drawings 17 7 0 INSTALLATION DRAWINGS Figure 7 Outline drawing 250A STS2 PDU ...

Page 42: ...Installation Drawings 34 Figure 24 Electrical field connections 250A STS2 PDU input with CB3 ...

Page 46: ...Installation Drawings 38 Figure 28 Electrical field connections 800A STS2 PDU input with CB3 ...

Page 63: ...Installation Drawings 55 Figure 45 Control wiring 800A STS2 PDU left side distribution ...

Page 64: ...Installation Drawings 56 Figure 46 Control wiring 800A STS2 PDU right side distribution ...

Page 65: ...Installation Drawings 57 Figure 47 Control connection location 250A STS2 PDU ...

Page 66: ...Installation Drawings 58 Figure 48 Control connection location 400 800A STS2 PDU ...

Page 68: ...Installation Drawings 60 Figure 50 Control wiring for the programmable relay board option ...

Page 69: ...Installation Drawings 61 Figure 51 Control wiring for the input contact isolator board option ...

Page 70: ...Installation Drawings 62 Figure 52 Control wiring for comms board ...

Page 71: ...Installation Drawings 63 Figure 53 Control wiring for the internal modem option ...

Page 72: ...Installation Drawings 64 Figure 54 Control wiring for the Network Interface Card NIC option ...

Page 73: ...Installation Drawings 65 Figure 55 Control wiring for the RS 232 Port ...

Page 74: ...Installation Drawings 66 Figure 56 Control wiring for remote source selection option ...

Page 75: ...Installation Drawings 67 Figure 57 Color LCD touch screen display ...

Page 155: ......