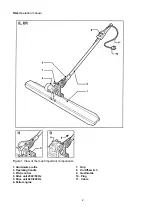

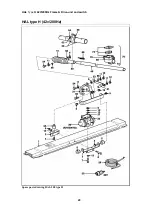

HAL

Operation manual

OPERATION OF THE BULLFLOAT, HAL200/ER

1

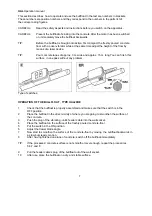

Check that the bullfloat is properly assembled and that the switch is in the OFF position.

2

Put the plug of the drive-unit’s feeder cable in the wall socket.

3

Place the bullfloat in the direct vicinity of where you are going to smoothen the surface

of the concrete-floor.

4

Place the bullfloat on the surface of the freshly poured concrete, and turn the speed regulator

slowly to the required revolutions.

5

Adjust the trowel blade angle.

6

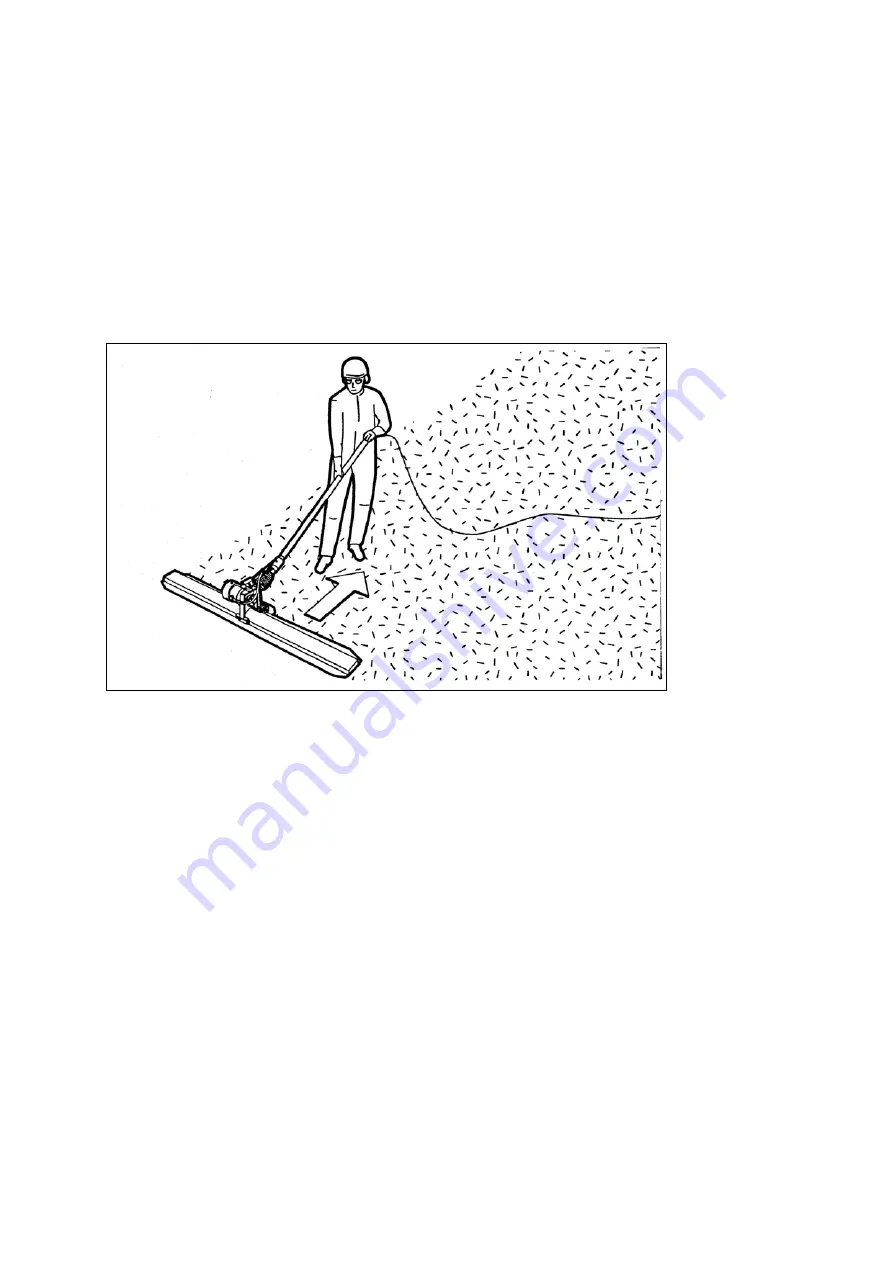

Now start to smoothen the surface of the concrete floor by moving the bullfloat backwards

in a slow but steady motion.

7

After having finished one lane of concrete, switch of the bullfloat immediately, by turning

he speed regulator’s knob to the position MINIMAL.You will hear a CLICK.

Worksituation during smoothing and compacting of the concrete floor.

Tip: if the processed concrete surface is not smooth or level enough, repeat the procedures 5,6,7 and 8

8

Pull the plug of the feeder cable out of the wall socket.

9

After use, place the bullfloat on a dry and stable surface.

OPERATION OF THE BULLFLOAT, HAL200/H

CAREFUL: Make sure that the frequency-convertor is running before connecting the bullfloat.

1

Check that the bullfloat is properly assembled and that the switch is in the OFF position.

2

Place the bullfloat in the direct vicinity of where you are going to smoothen the surface of

the concrete-floor.

3

Insert the 42V.plug into the socket of the frequency-convertor.

4

Switch-on the frequency-convertor.

5

Place the bullfloat on the freshly poured concrete.

6

Put the switch in the ON position.(PostionI)

7

Adjust the trowel blade angle.

8

Now start to smoothen the surface of the concrete by moving the bullfloat backwards in a slow

and steady motion.

9

After having finished one lane of concrete put the switch in the 0 position.

10

Disconnect the plug from the frequency-convertor.

11

After use, place the bullfloat on a dry and clean surface.

8