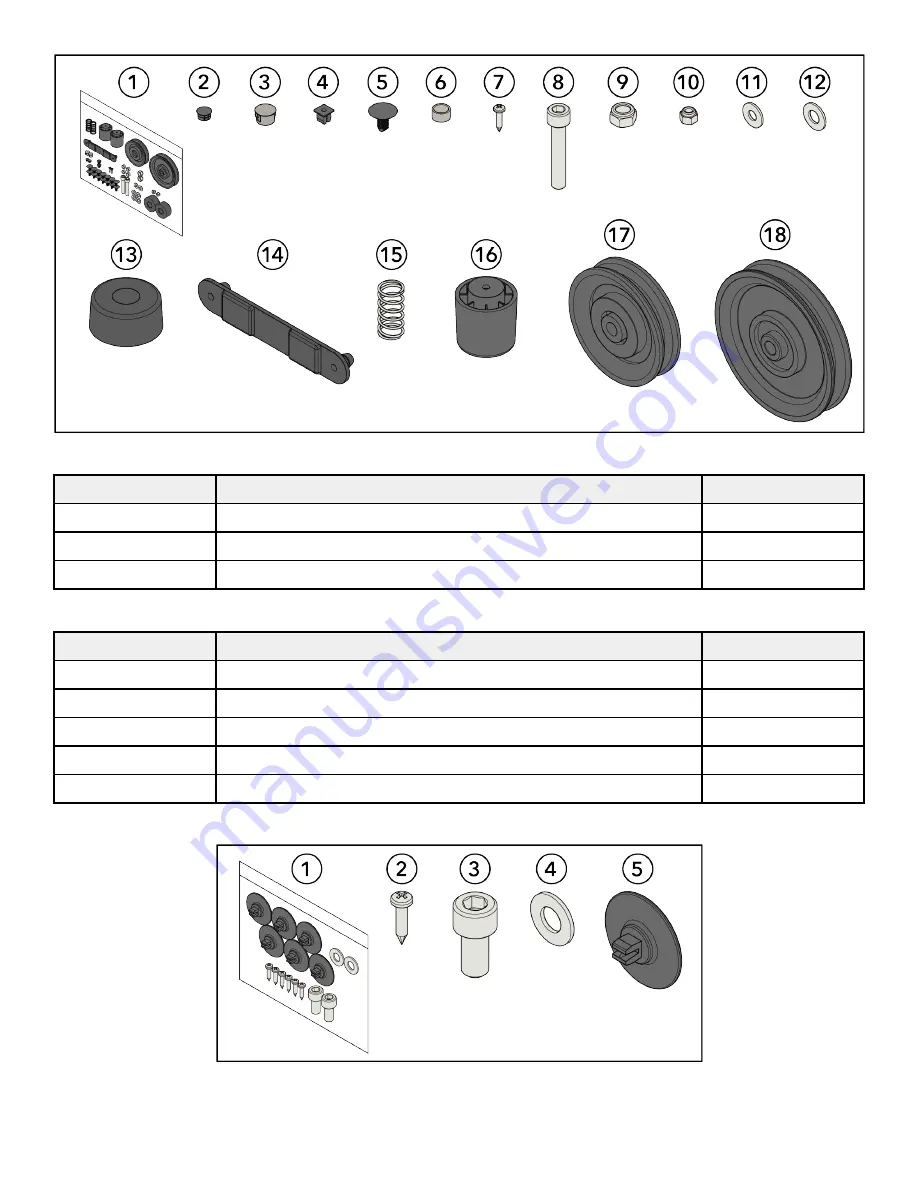

OP-BT Tower Hardware Kit

Optional: Front Shroud Kit Components

Item

Description

Qty.

1

Front Shroud, Left

1

2

Front Shroud, Right

1

3

Bottom Cap

1

Optional: Front Shroud Kit Hardware Kit

Item

Description

Qty.

1

Front Shroud Hardware Kit

1

2

Screw, M4.2 x 0.7, Phillips

6

3

Screw, M10 x 1.5, 20mm

2

4

Washer, Flat 3/8"

2

5

Grommet, Shroud Retainer

6

Optional: Front Shroud Kit Hardware Kit

Page 9 of 40

Summary of Contents for Axiom OP-BT

Page 1: ...Axiom Series Biceps Curl Triceps Extension OP BT Assembly Instructions 1015200 0001 REV AA ...

Page 2: ......

Page 8: ...Product Labels General Warning Serial Number Pinch Hazard Page 6 of 40 ...

Page 42: ...Foot Dimensions Use below image to determine foot specifications Page 40 of 40 ...

Page 43: ......

Page 44: ......