22

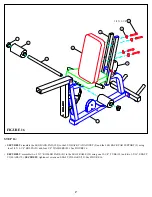

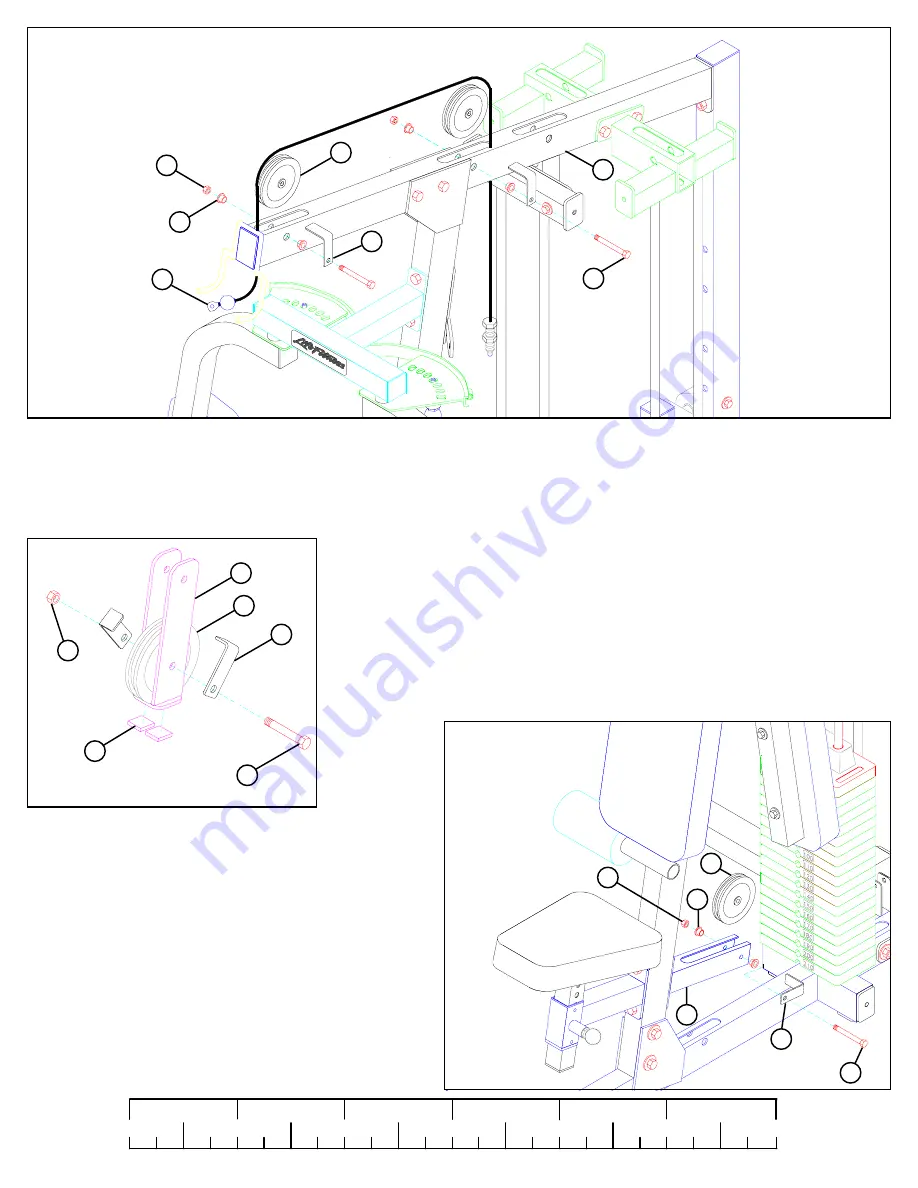

STEP 22:

FIGURE 22

•

SECURELY

assemble two 4-1/2” PULLEYS (48) into the slots of the TOP BOOM (30) using two 3/8 X 2-3/4” BOLTS (90), four 3/8” FLANGE

SPACERS (69), two 2-7/8” X 2-1/4” CABLE CLIPS (116) and two 3/8” LOCK NUTS (82).

(NOTE: Loop the cable around each pulley prior to

inserting it in the the slot.)

0

1

2

3

4

5

6

1/2

1/2

1/2

1/2

1/2

1/2

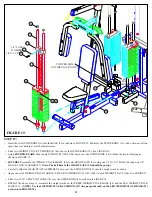

•

SECURELY

assemble one 4-1/2” PULLEY (48) to the FLOATING

PULLEY STOP (10) using one 3/8 X 2-3/4” BOLT (90), one 2-7/8” X

2-1/4” CABLE CLIP (116), two 3/8” FLANGE SPACERS (69), and

one 3/8” LOCK NUT (82) as shown in FIGURE 24.

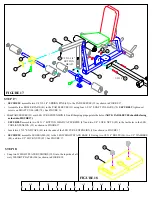

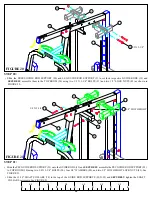

FIGURE 23

FIGURE 24

STEP 23:

•

SECURELY

assemble one 4-1/2” PULLEY (48) to the FLOATING PULLEY BRACKET (55)

using one 3/8 X 2” BOLT (89), two 2-7/8 X 1” CABLE CLIPS (67) and one 3/8” LOCK

NUT (82) as shown in FIGURE 23.

STEP 24:

•

Route the threaded end of the LAT CABLE (42) through the TOP BOOM (30) as shown in FIGURE 22.

3/8 X 2” 89

82

60

48

55

• Apply two 1 X 1” GLIDES (60) to the FLOATING PULLEY BRACKET (55) as shown.

82

LAT CABLE 42

48

82

48

11

69

90

3/8 X 2-3/4”

3/8 X 2-3/4” 90

30

69

116

67

116