SM83 Unpacking & Assembly Instructions

10

C.

Prepare the weight stack.

Slide the guide rods (2) through the weight stacks (1)

as shown below. Place rubber bumpers (3) on the bottoms of each guide rod.

Make sure the pull pin (4) is in the bottom weight plate.

D.

Flip over the weight stacks.

When shipped, the weight stacks have the pull pins

facing upward. You will need to flip the stacks over so that the pull pins are facing

outward when they are loaded onto the machine. Since the pull pins will be facing

downward when they are flipped over, it is recommended that you put the stacks

on a padded carpet to keep the pins from being damaged.

E.

Set the weight stacks onto the machine.

Using a piano dolly, lift the weight

stacks over the bottom plate and set the stacks onto the rubber bumpers with the

plate numbers facing outward. The 300 lb weight stacks need to be facing the

“sides” of the cells (where the benches will be attached- number 8 in Figure 9).

The 190 lb weight stacks will need to be facing the “outsides” and “insides” of the

cells (where the tricep pulley adjustable pulleys will be attached- number 9 in

Figure 9). Make sure the pull pins are facing outward.

C. Prepare the weight stack-

add bumpers to bottom, insert

guide rods, put pull pin in

bottom stack.

D. Flip over the weight stack

onto piano dolly.

E. Hoist the weight

stack onto the machine.

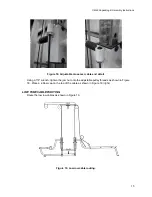

F. With the top plate on the guide rods, bolt on the top plate to the top of the cells as

shown in Figure 11 using a 9/16” socket and combination wrench and the 3” bolts

(with cap washers) that were previously inserted.

Figure 11. Bolt on the top plate.