7

ASSEMBLY INSTRUCTIONS

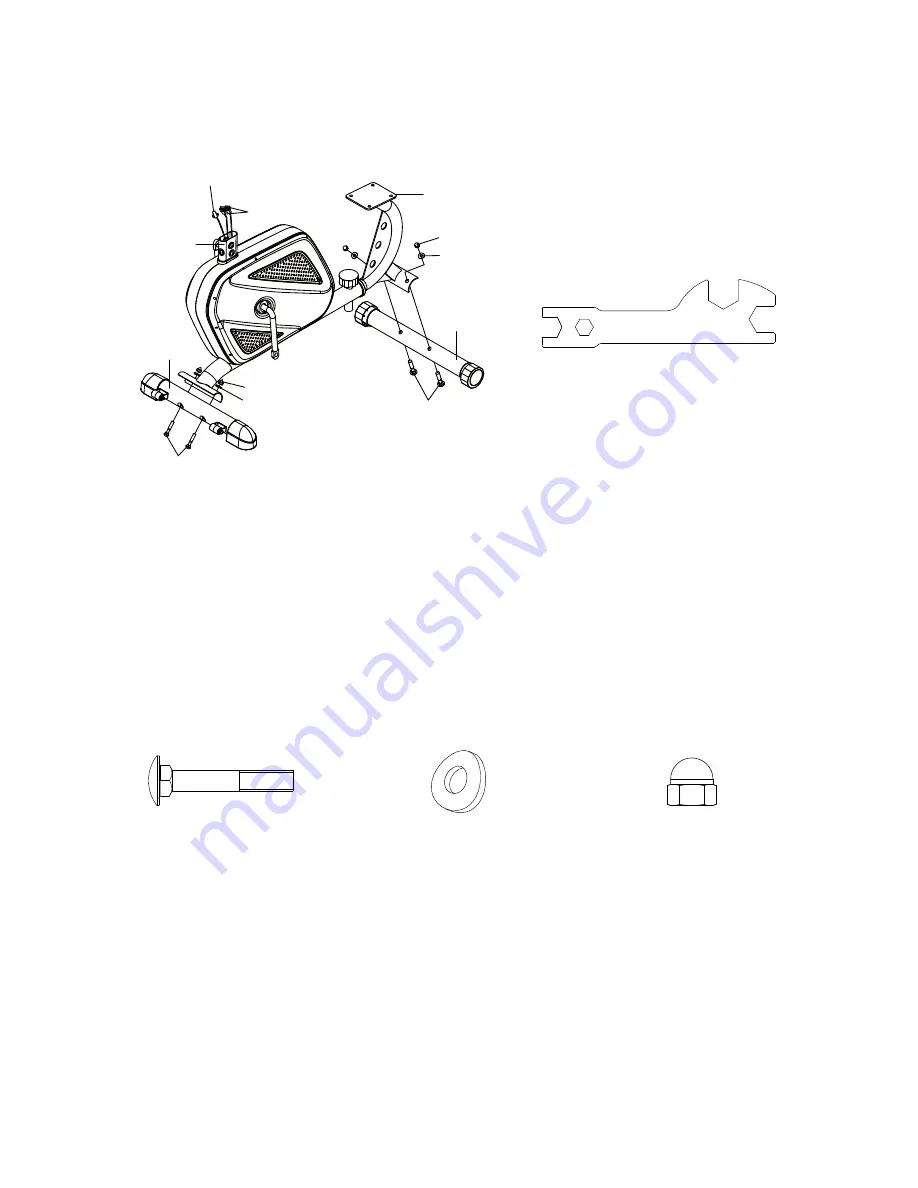

1. Front and Rear Stabilizers Installation

Position the Front Stabilizer (2) in front of the Front Main Frame (5) and align bolt holes.

Attach the Front Stabilizer (2) onto the front curve of the Front Main Frame (5) with two

M10x57 Bolts (30), two Ø10.5xØ25x2 Curve Washers (31), and two M10 Cap Nuts (32).

Tighten cap nuts with the Multi Hex Tool provided.

Position the Rear Stabilizer (4) behind the Rear Main Frame (3) and align bolt holes.

Attach the Rear Stabilizer (4) onto the rear curve of the Rear Main Frame (3) with two

M10x57 Bolts (30), two Ø10.5xØ25x2 Curve Washers (31), and two M10 Cap Nuts (32).

Tighten cap nuts with the Multi Hex Tool provided.

Hardware:

Tool:

Multi Hex Tool

3

2

5

30

32

31

31

30

4

32

65

61

(30) Bolt M10x57

4 PCS

(31) Curve Washer

Ø10.5xØ25x2

4 PCS

(32) Cap Nut M10

4 PCS