10

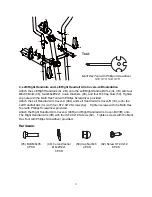

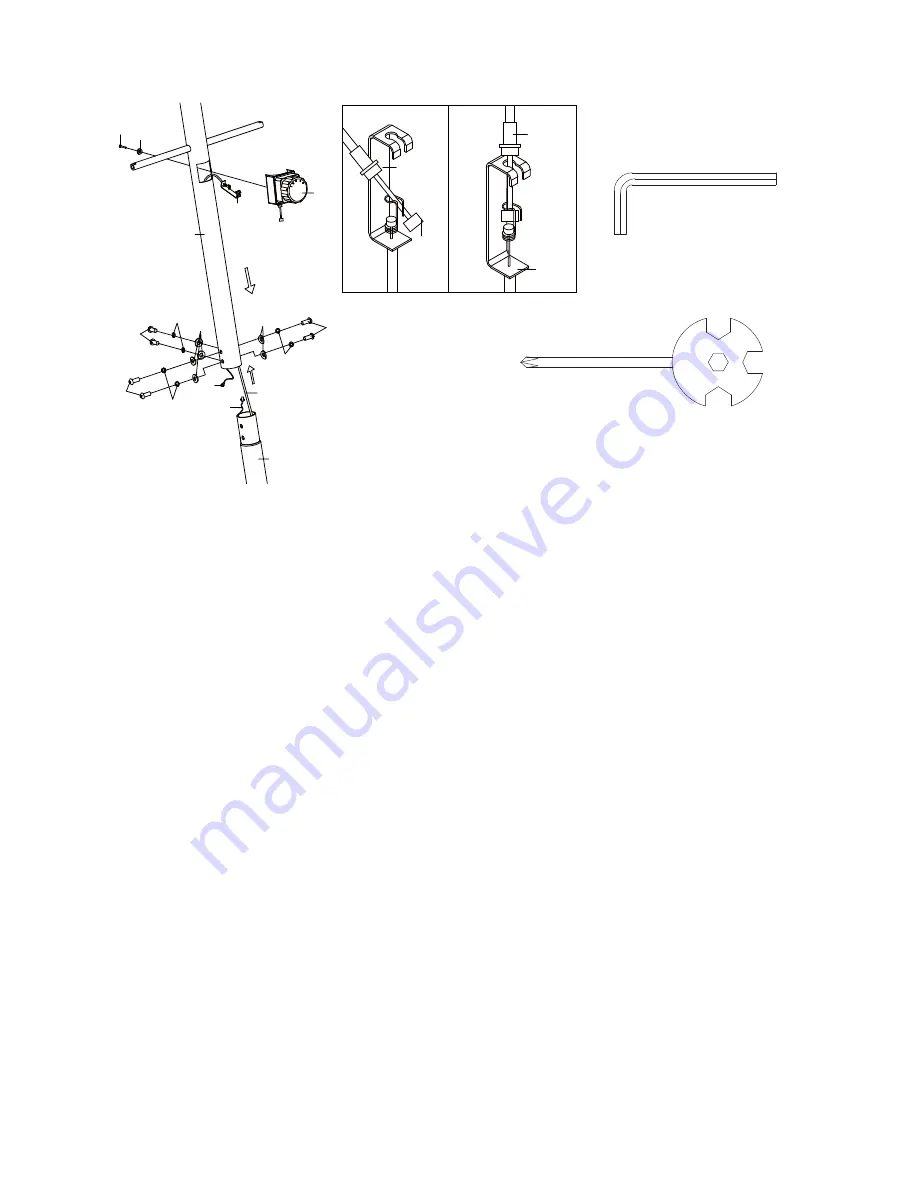

2. Front Post and Tension Control Knob Installation

Remove six M8x16 Bolts (41), six Ø20xØ8x1.5 Big Curve Washers (42), and six Ø8 Spring

Washers (55) from the Main Frame (1). Remove bolts and washers with the S6 Allen

Wrench provided.

Insert the Tension Cable (30) through into the bottom hole of Front Post (5) and pull it out

from the square hole of Front Post (5).

Connect the Sensor Wire II (68) from the Main Frame (1) to the Sensor Wire I (67) from the

Front Post (5).

Insert the Front Post (5) onto the tube of the Main Frame (1) and secure with six M8x16

Bolts (41), six Ø20xØ8x1.5 Big Curve Washers (42), and six Ø8 Spring Washers (55) that

were removed. Tighten bolts and washers with the S6 Allen Wrench provided.

Remove the Ø20xØ5.2 Curve Washer for Tension Control Knob (64) and M5x45 Bolt for

Tension Control Knob (65) from the Tension Control Knob (54). Remove bolt and curve

washer with the Multi Hex Tool with Phillips Screwdriver provided.

Put the cable end of resistance cable of Tension Control Knob (54) into the spring hook of

Tension Cable (30), see Figure A. Pull the resistance cable of Tension Control Knob (54)

up and force it into the gap of metal bracket of Tension Cable (30), see Figure B. Attach the

Tension Control Knob (54) onto the Front Post (5) with the Ø20xØ5.2 Curve Washer for

Tension Control Knob (64) and M5x45 Bolt for Tension Control Knob (65) that were removed.

Tighten bolt and curve washer with the Multi Hex Tool with Phillips Screwdriver provided.

Tool:

Allen Wrench S6

Multi Hex Tool with Phillips Screwdriver

S10, S13, S14, S15

1

5

30

64

65

68

67

41

42

54

41

55

55

55

41

42

30

B

A

54

54

30

30