25

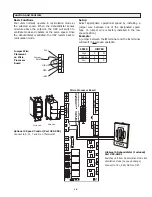

Reinstalling the Electrical Box:

21. Remove the two snap plugs from the opposite

side of the cabinet for electrical and control wires.

22. Install the two snap plugs in the cabinet holes on

the side of the HRV which electrical box was

originally removed from.

23. Route wires for both blower motors to opposite

side of HRV cabinet where electrical box is to be

installed.

24. Install the grounding continuity screw in both

the upper and lower blower assemblies on the

opposite side of the HRV where electrical box

is now installed.

25. Fasten the electrical box to the cabinet of

the HRV using the 4 screws that were

previously removed.

26. Remove the snap plug from the blower divider

panel and install plastic snap bushing provided

in manual bag.

27. Install snap plug in hole in blower divider

panel where lower blower motor wires were

originally removed from.

28. Route the lower blower motor wires through the

hole in the divider panel into the electrical box.

29. Route upper motor wires into the electrical box.

30. Route damper motor wires into e-box and

connect the motor wires to the circuit board,

relays and capacitors using wiring diagram found

in manual for reverse installations.

31. Connect damper motor wires to circuit board

using wiring diagram found in manual for reverse

installations.

32. Route thermistor wire from electrical box,

through hole in the top core support panel,

and secure the blue end to the thermistor

bracket in front of the damper motor using a

plastic cable tie.

33. Connect the thermistor to the circuit board

in the electrical box.

34. Putty holes closed in blower divider panel and

top core support panel with wires protruding

through.

35. Install the large single door panel on the now

back of the cabinet where electrical box was

removed from and fasten using the eight

machine screws.

36. Reversing of the HRV is now complete.

Continue with the installation of the HRV.

Reverse Installation of the HRV

Continued

Summary of Contents for 1200 POOL

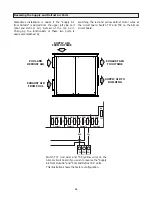

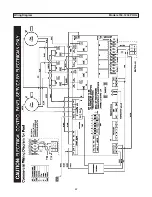

Page 27: ...27 Wiring Diagram Models 700 1200 POOL ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 31: ...31 ...

Page 32: ...info lifebreath com T 1 855 247 4200 F 1 800 494 4185 69 POOL 100516 ...