Page | 4

Assembly Instructions

Assembly Tips

The LifeCORE CD450 is made from the best materials and has been tested and received a quality

control review prior to its packaging to ensure the correct parts and proper fitting of each component.

This machine was designed to limit the amount of assembly needed by a consumer.

Before assembly of your product, distinguish a proper and appropriate location for the unit where

there is easy access to an electrical outlet with a surge protector. Unpack the box in a clear work

area to allow smooth assembly. Remove all of the parts from the packing material; however, do not

discard packing material until assembly is complete. Double check packing materials to ensure no

missing parts were left behind.

Note that some hardware may be preassembled to components in order to help with assembly; tools

have also been provided to assist with assembly.

Getting Started

Unpack the box in a clear location, remove all packaged parts from the box and lay each part out on

the floor. Double check all packaging material for missing pieces, do not dispose of any packing

material until assembly is complete and unit is working properly. The final location of the machine

should be placed on a clean level surface near an electrical outlet.

Hardware Bags -

Locate all hardware bags for assembly. Bags will be labeled

Figure 1

through

Figure 11

. Tools have been provided to assist with product assembly.

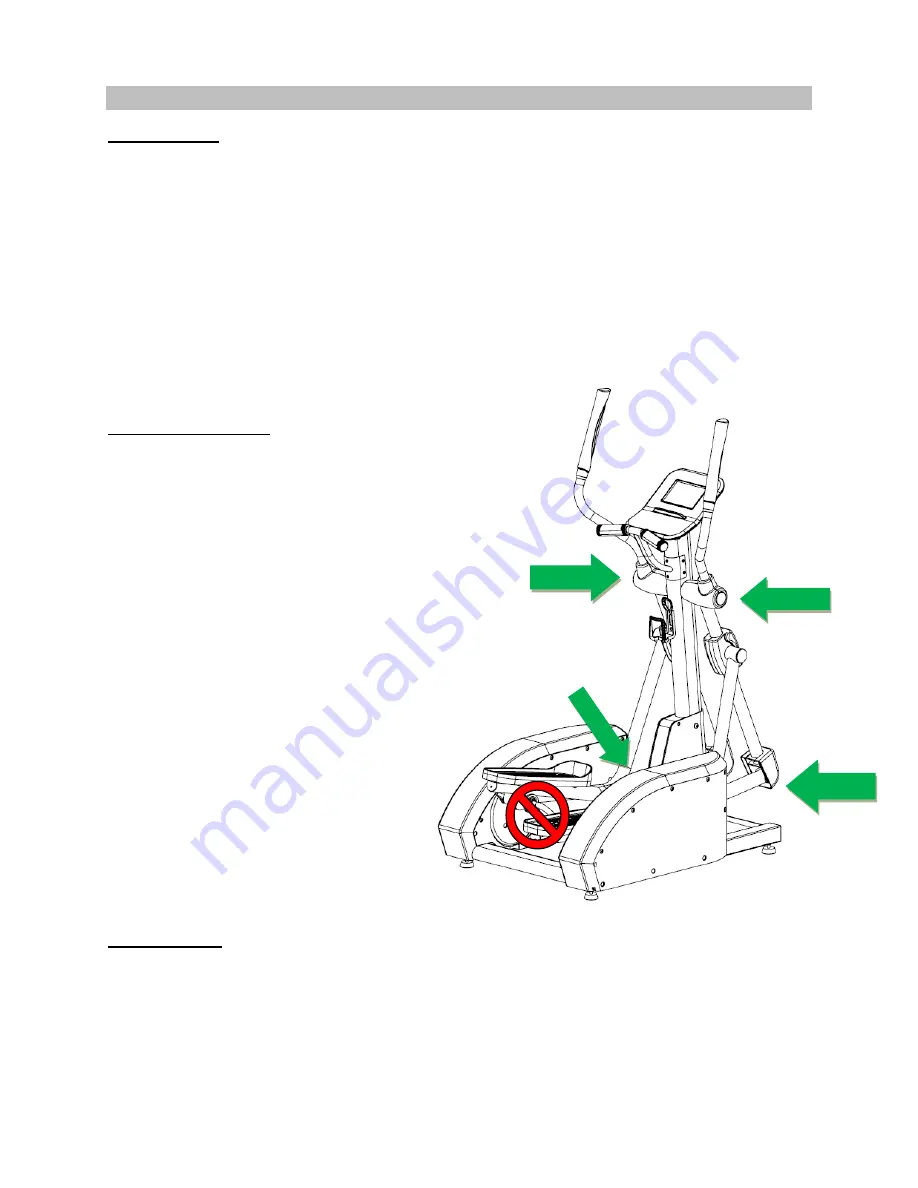

Figure 3

Assembly Assistance

In each CD450 assembly pack, there is a

tube of grease for assembly purposes. This

tube of grease must be applied to the pivot

points during assembly. At no

time

should this grease be applied on to the

rubber wheels parts #2CUB Shaft Wheel

w/ball bearing.

Figure 3

– Green Arrows

During Step 3 assembly, apply grease to

the console tube pivot points

on each

side. Once the arms are secure, apply

some additional grease to the bearings,

then secure arm with Figure 3 hardware.

Figure 5

– Green Arrows

During Step 5 assembly, apply grease to

the pedal tube and handrail assembly tube

pivot point

on each side. In addition,

apply grease to the M10 * 81.5 Hex Bolt.

NOTE: DO NOT USE WD-40 OR

SILICONE SPRAY

– This will increase

squeaking noise.

Figure 3

Figure 5