Page

|

22

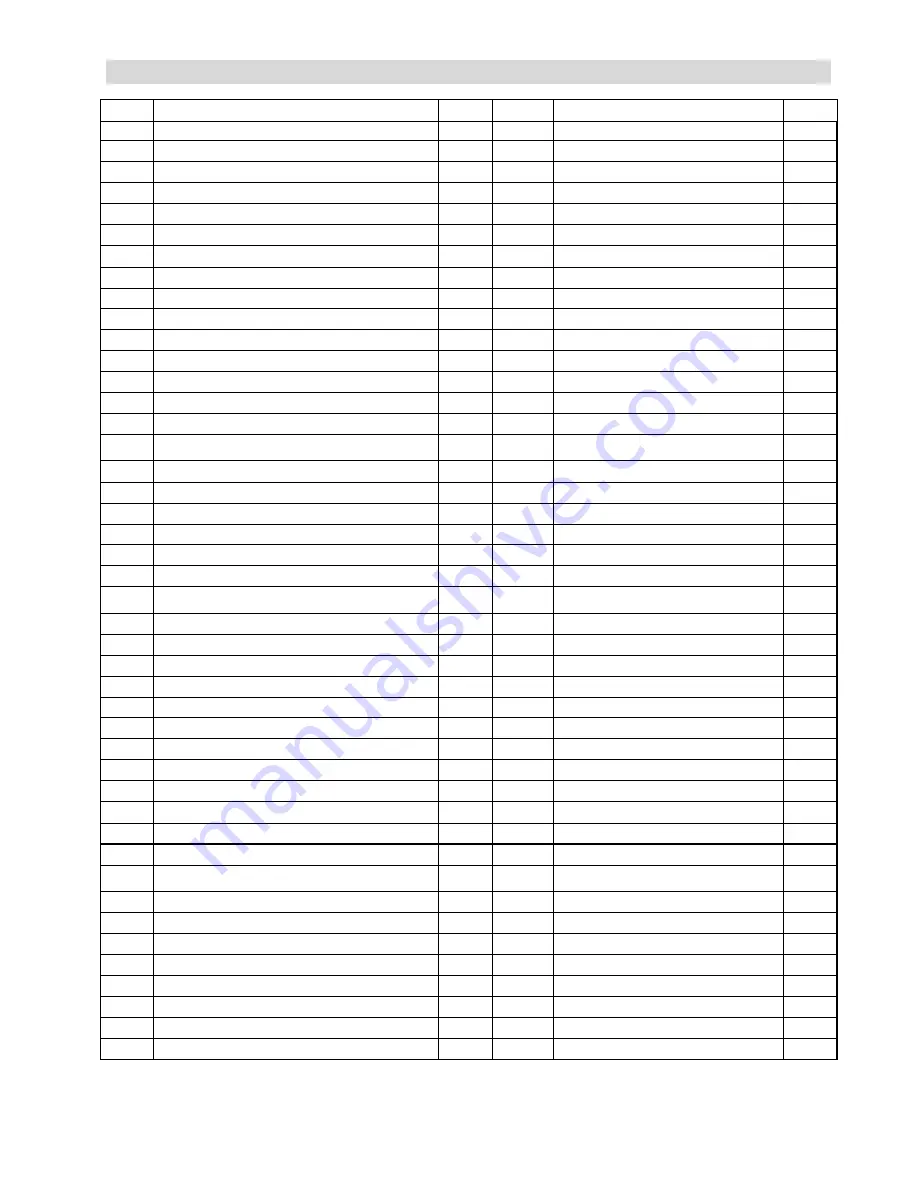

Parts List & Parts Diagram

P/N

DESCRIPTION Qty

P/N

DESCRIPTION

Qty

A MAIN

FRAME

1

A51 BELT WHEEL

∮

360(J10)

1

A1 SENSOR

WIRE

1

A52 BELT

530(1355MM)*J8

1

A2 CONTROLLER

WIRE

1

A53 NUT

M8

10

A3 KNOB

1

A54

OSCILLATING AXLE BASE (R)

1

A4

CONNECTION SLICE 40 (4T)

4

A55

OSCILLATING AXLE BASE (L)

1

A5

INCLINE MOTOR SENSOR WIRE

1

A56

HANDLEBAR SUPPORTING COVER

2

A8

INCLINE MOTOR CONTROLLER BOX

1

A57

BEARING 6905(TPX)

4

A9 SCREW

M5*10

2

A58 END CAP

∮

4”

2

A10 ADAPTOR

1

A59 FIX CUSHION

∮

50 TPR

2

A11 DC

WIRE

1

A60 WASHER M6*2T*

∮

19

2

A12 SOCKET

2

A61 SCREW

3/16”*5/8”

2

A13

NUT

1

A62

FRONT CONNECTING SHAFT

2

A14 SCREW

M3*8

4

A63 END

CAP

1

A15 SENSOR

1

A64 BUSH

∮

8*(

∮

12+

∮

15)

4

A16 MOTOR

1

A65 CLIP(R36)

12

A17

CONNECTION CABLE BETWEEN OVERLOAD SWITCH

AND SWITCH AC POWER

1 A67

BEARING SLEEVE

∮

42*3T

12

A18

BEARING 6005(TPX)

2

A69

NUT M4

10

A19

BRAKE DEVICE (3T)

1

A71

CRANK CONNECTING SHAFT

2

A20 SCREW

M6*43

1

A72 BEARING

2203(MRB)

2

A21 SCREW

M8*16

1

A73 NUT

M10

2

A22 WASHER(10*12)

2

A74

CLIP(R40) 2

A23 OVERLOAD

SWITCH

1

A75

BUSH L724

∮

8(

∮

11.9+

∮

15)

8

A24

CONNECTION WIRE BETWEEN OVERLOAD SWTICH

AND SWITCH AC POWER

1 A76

NUT

2

A25

POWER CONNECTION WIRE

1

A77

FLAT KEY 7*7*20MM

2

A26 SWITCH

AC

POWER

1

A78 WASHER M17*

∮

35*2T

12

A27

POWER CORD SOCKET

1

A79

SCREW M8*50

4

A28

SCREW M3*10

2

A80

FRONT PEDAL SUPPORTING TUBE

2

A29 SCREW

M8*10

2

A81 WASHER

∮

10*

∮

27*2T

2

A30 TRANSPORTATION

WHEEL

2

A82 SCREW

M10*40MM

2

A31 SCREW

M8*45

4

A83 NUT

4

A32 PRESSING

PIPE

1

A84 SCREW

2

A33

WASHER

∮

10*

∮

23*2T

3 A85

SPRING

2

A34

BEARING 6200(MRB)

2

A86

MOTOR PUSH ROD

2

A35

SCREW M10*30

1

A87

AXLE FOR MOTOR PUSH ROD

4

A36

J SHAPE SCREW M6

1

A88

NUT

4

A37

CONNECTION WIRE BETWEEN SWITCH AC POWER

AND POWER CORD

1 A89

NYLON

SLEEVE

4

A38

WASHER M6*

∮

16*2T

1

A90

PUSH ROD BRACKET

4

A39 GROUND

WIRE

1

A91 END

CAP

1

A40 POWER

CORD

1

A92

SPACER SHIM

2

A41

FLYWHEEL

∮

327

1 A93

SCREW

M8*25MM

4

A42 NUT

3/8”

2

A94 SCREW M6*40

4

A43

TENSION CABLE 400MM

1

A95

SCREW 5/32”*3/4”(M4*19MM)

11

A44 SCREW

M5*10

4

A96 NUT M6

6

A45

TURING PLATE

2 A97

SIDE DECORATION HOUSING SET(L)

2

Summary of Contents for VST-V8

Page 1: ...User s Product Manual LifeCORE VST V8 Variable Stride Trainer...

Page 6: ...Page 5...

Page 25: ...Page 24...

Page 26: ...Page 25...