10

Sea Horse Pump Installation and User’s Guide

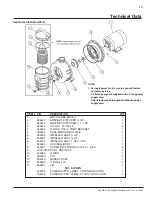

Pump Disassembly, continued.

f. To remove the stationary ceramic seal seat, first loosen the four motor bolts which run through the entire

length of the motor into the bracket diffuser. Remove the bracket diffuser from the motor. Press the

ceramic seat and rubber gasket out of the bracket diffuser.

g. Clean the bracket diffuser seal area and lubricate with soapy water. Press the new ceramic seal and gasket

into the bracket diffuser, being sure it is fully seated. Wipe off the ceramic sealing surface with a clean

tissue to remove oily fingerprints or foreign substances.

Pump Reassembly/Seal Replacement

1. Place the bracket diffuser on the motor and carefully align the four motor through bolts. Secure the housing

onto the motor being careful not to overtighten the bolts. Gradually bring bolts up to final tightness by moving

across diametrically and in a criss-cross pattern.

2. Screw the impeller with new rotating seal onto the motor shaft. Rotate the motor shaft to make sure the impeller

is not touching the bracket diffuser.

3. Clean the bracket diffuser o-ring and check to make sure it is in position. Replace the motor and bracket

diffuser on the front pump housing body and bolt into position with six (6) bolts. Gradually bring bolts up to

final tightness by moving across diametrically and in a criss-cross pattern.

CAUTION! DO NOT overtighten the bolts.

4. Fill the pump with water.

5. Reinstall the pump lid and locking ring.

6. Reprime the system. Refer to initial start-up procedures to restart the pump.

The Shaft Seal

1. The Shaft Seal consists primarily of two parts, a rotating member and a ceramic seal.

2. The pump requires little or no service other than reasonable care, however, a Shaft Seal may occasionally

become damaged and must be replaced.

The polished and lapped faces of the seal could be damaged if not handled with care.

In mild climate area, when temporary freezing conditions may occur, run your filtering equipment

all night to prevent freezing.

Be sure not to scratch or mar the polished shaft seal faces; seal will leak if faces

are damaged.