2

Sea Horse Pump Installation and User’s Guide

4. Provide space and lighting for routine maintenance access. Do not mount electrical controls directly

over pump.

5. The pump should be installed as near to the pool or spa as practical. Avoid installing the pump more

than a few feet above the water level. Suction lifts of more than five feet will cause very long priming

times. Pump will not lift more than 8 feet.

6. The location should provide for adequate floor drainage to prevent flooding.

7. Provide for the need to remove the pump for potential service by providing valves or other means to

disconnect the pump suction and discharge.

8. Never store pool chemicals within 10 ft. of your pool filter and pump. Pool chemicals are corrosive and

should always be stored in a cool, dry, well ventilated area.

WARNING

Chemical fumes and/or spills can cause severe corrosive attack to the filter and pump structural components. Structurally

weakened filter or pump components can cause filter, pump or valve attachments to separate and could cause severe

bodily injury or property damage.

9. Assemble piping and pipe fittings to pump and valve. All piping must conform to local and state

plumbing and sanitary codes.

10. Use threaded seal tape or pipe sealants on all male connections of pipe and fittings. Use only pipe

sealant compounds suited for plastic pipe. Support pipe to prevent strains on filter, pump or valve. DO

NOT USE PETROLEUM BASED PRODUCTS.

11. Avoid over tightening the pipe threads when connecting fittings to the pump. Proper procedure is to

apply a pipe sealant to the thread and then install hand tight plus 1-1/2 turns. DO NOT OVER

TIGHTEN.

12. Long piping runs and elbows restrict flow. For best efficiency, use the fewest possible fittings, large

diameter pipe (at least 1-1/2") and locate equipment as close to the pool as possible. The pump suction

line should not be smaller than the pipe size on the inlet of the pump.

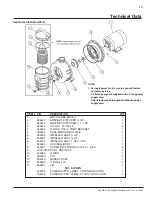

Installation

1. Check carton for any evidence of damage due to rough handling in shipment. If carton or any pump

components are damaged, notify freight carrier immediately.

2. After inspection, carefully remove pump from carton.

3. The pump should be secured to

a flat solid foundation, high enough to prevent flooding of the motor. A

sheltered location is best, being sure to allow for adequate ventilation.