12

6. Set up the columns at e desired place facing each other. Then lift up the carriage to first

latch locking height (about one foot high). (Fig. 6)

Attention: (1) the main column is suggested at the left hand with

vehicle head forward.

(2) the distance between column to wall is suggested to be

at least 2 feet for safe.

Fig. 7a

Fig. 7b Fig. 6

7. Assemble the ceiling safety device to the overhead cross beam. (Fig. 7a, 7b & 7c) Then

Install the beam on the column tops. (Fig. 7d )

Fig. 7c Fig. 7d

8. Mount the cable seat with roller on the beam base at the top of the column. (Fig. 8)

Fig.8a Fig. 8b

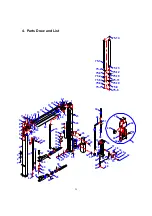

Summary of Contents for 165948BLK

Page 7: ...7 Fig 1 Front View Spec...

Page 8: ...8 Fig 2 Top View Spec...