165982HLK

Dec. 2020

3

Safety Cautions

1.1 Important statements

Please do note the tonnage mark on the machine. Do not try to lift any load that exceeds the rated

lifting capacity.

Please read this manual carefully before installation and use of the lift, to avoid any property loss

or personal injury caused by faulty operation.

No one is allowed to modify the control part and other mechanical parts of the machine without

the manufacturer’s permission.

1.2 Instructions for qualification of operators and users

1.2.1 Only personnel who have received professional training are allowed to operate and use

the lift.

1.2.2 Electrical connection must be performed by qualified electricians.

1.2.3 Nonprofessionals shall not approach the lifting area.

1.3 Cautions

1.3.1 Do not install the lift on asphalt or tar ground. Concrete thickness must meet requirement.

1.3.2 Please read and understand Safety Cautions carefully before operation of the lift.

1.3.3 The lift shall not be used outdoor if not being customized to special requirements.

1.3.4 Hands and feet shall be away from moving parts of the lift. Move hands and feet away

when the machine is descending, to avoid being crushed.

1.3.5 Only personnel who have received professional training are allowed to operate and use

the lift.

1.3.6 Operators are not allowed to wear fat and loose clothes, to avoid being clamped by any

moving part when the machine is descending or rising.

1.3.7 Ground around the lift must be kept clean and tidy, with no stacking of materials, in order

to avoid accident.

1.3.8 The lift is designed to lift the entire car, not part of it. Do not try to lift any car beyond the

rated lifting capacity.

1.3.9 Do make sure the safety lock of the lift is locked when personnel are working undercar.

1.3.10 Lifting block of the lift must be put at a place suggested by the car manufacturer, and then

the car shall be lifted slowly. Check the car is stable without any risk of tipping, overturn or

falling, before lifting it to the desired height.

1.3.11 Check whether any part is broken and check synchronicity of the machine and flexibility of

moving parts at any time. Perform regular maintenance. Once any anomaly is detected,

stop use immediately and contact your dealer.

1.3.12 Please lower the machine to the lowest position and turn off power after operation.

1.3.13 It is not allowed to modify any part of the lift without the manufacturer’s permission.

Summary of Contents for 165982HLK

Page 1: ...Dec 2020 MOBILE 4 COLUMN PARKING LIFT Model 165982HLK Installation Operation Manual...

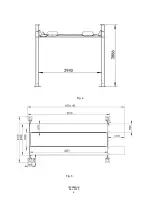

Page 6: ...165982HLK Dec 2020 6 Fig 4 Fig 5...

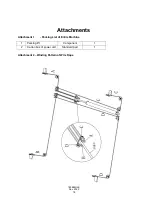

Page 19: ...165982HLK Dec 2020 19 Attachment 3 Hydraulic Schematic Diagram...

Page 21: ...165982HLK Dec 2020 21 Parts Drawing Fig 4 Parts Drawing Fig 5...

Page 22: ...165982HLK Dec 2020 22 Parts Drawing Fig 6 Parts Drawing Fig 7...

Page 23: ...165982HLK Dec 2020 23 Parts Drawing Fig 8 Parts Drawing Fig 9...