35

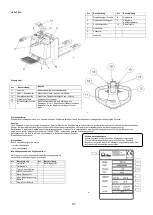

Battery maintenance

Do not overuse battery:

– Do not over discharge the battery, this will shorten its life

– As soon as the battery status indicator (11fig. 3) shows that battery is low, please recharge it

Inspection for electrolyte:

– Inspection for electrolyte level must be performed every week.

– When electrolyte level is low, you must add distilled water to the appropriate level

– Do not use the truck if the electrolyte level is low

Battery maintenance

The battery cell covers must be kept dry and clean. The terminals and cables must be clean, secure and have a light coating of dielectric grease. Batteries with non

insulated terminals must be covered with a non slip insulation mat.

Battery Disposal

Batteries may only be disposed of in accordance with national environmental protection regulations or disposal laws. The manufacturer’s disposal instructions must

be followed.

Batteries contain an acid solution which is poisonous and corrosive. Therefore always wear protective clothing and eye protection when carrying out work on

batteries. Above all avoid any contact with battery acid.

Nevertheless, should clothing, skin or eyes come in contact with acid the affected parts should be rinsed with plenty of clean water-where the skin or eyes are

affected call a doctor immediately. Immediately neutralise any spilled battery acid.

Only batteries with a sealed battery container may be used.

The weight and dimensions of the battery have considerable affect on the operational safety of the truck. Battery equipment may only be replaced with the

agreement of the manufacturer.

7.0 MAINTENANCE

Operational safety and environmental protection

– The servicing and inspection operations contained in this chapter must be performed in accordance with the intervals indicated in the servicing checklists.

– Any modification to the pallet truck assemblies, in particular the safety mechanisms, is prohibited. The operational speeds of the truck must not be changed

under any circumstances.

– Only original spare parts have been certified by our quality assurance department. To ensure safe and reliable operation of the pallet truck, use only the

manufacturer's spare parts. Used parts, oils and fuels must be disposed of in accordance with the relevant environmental protection regulations. For oil changes,

contact the manufacturer’s specialist department.

– Upon completion of inspection and servicing, carry out the activities listed in the “Recommissioning” section.

Maintenance Safety Regulations

Maintenance personnel

Industrial trucks must only be serviced and maintained by the manufacturer’s trained personnel. The manufacturer’s service department has field technicians

specially trained for these tasks. We therefore recommend a maintenance contract with the manufacturer’s local service center.

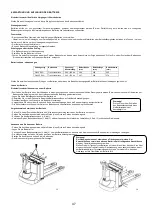

Lifting and jacking up

When the is to be lifted, the lifting gear must only be secured to the points specially provided for this purpose.

When jacking up the truck, take appropriate measures to prevent the truck from slipping or tipping over (e.g. wedges, wooden blocks).

You may only work underneath a raised load handler if it is supported by a sufficiently strong chain.

Cleaning

Do not use flammable liquids to clean the industrial truck.

Prior to cleaning, all safety measures required to prevent sparking (e.g. through short circuits) must be taken. The battery connector must be removed.

Only weak suction or compressed air and non-conductive antistatic brushes may be used for cleaning electric or electronic assemblies.

Do not clean with pressurised water.

After cleaning the truck, carry out the activities detailed in the “Recommissioning” section.

Electrical System

Only suitably trained personnel may operate on the truck’s electrical system. Before working on the electrical system, take all precautionary measures to avoid

electric shocks. The battery connector must be removed.

Welding

To avoid damaging electric or electronic components, remove these from the truck before performing welding operations.

Settings

When repairing or replacing hydraulic, electric or electronic components or assemblies, always note the truck-specific settings.

Tyres

The quality of tyres affects the stability and performance of the truck. When replacing factory fitted tyres only used original manufacturer’s spare parts, as

otherwise the data plate specifications will not be kept.

When changing wheels and tyres, ensure that the truck does not slew (e.g. when replacing wheels always left and right simultaneously).

Servicing and inspection

Thorough and expert servicing is one of the most important requirements for the safe operation of the industrial truck. Failure to perform regular servicing can lead

to truck failure and poses a potential hazard to personnel and equipment.

The service intervals stated are based on single shift operation under normal operating conditions.They must be reduced accordingly if the truck is to be used in

conditions of extreme dust, temperature fluctuations or multiple shifts.

Warning!

1. Do not use dry cloth or fibre cloth to clean the battery,

2. Clean with wet cloth.

3. Disconnect battery connector

4. Wear glasses for protecting eyes

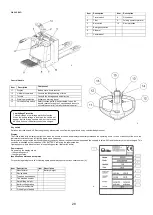

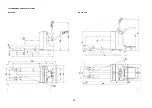

Summary of Contents for QX 20 EVO

Page 1: ......

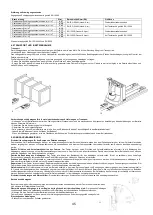

Page 6: ...4 3 0 DIMENSIONI E SPECIFICHE QX 20 EVO QX 20P EVO 7 8...

Page 19: ...17 3 0 DIMENSIONS ET SP CIFICATIONS QX 20 EVO QX 20P EVO 7 8...

Page 32: ...30 3 0 DIMENSIONS AND SPECIFICATIONS QX 20 EVO QX 20P EVO 7 8...

Page 45: ...43 3 0 ABMESSUNGEN UND SPEZIFIKATIONEN QX 20 EVO QX 20P EVO 7 8...

Page 58: ...56 3 0 DIMENSIONES Y ESPECIFICACIONES QX 20 EVO QX 20P EVO 7 8...

Page 72: ...70 3 0 DIMENS ES E ESPECIFICA ES QX 20 EVO QX 20P EVO 7 8...

Page 85: ...83 3 0 AFMETINGEN EN SPECIFICATIES QX 20 EVO QX 20P EVO 7 8...

Page 98: ...96 3 0 WYMIARY I SPECYFIKACJE QX 20 EVO QX 20P EVO 7 8...

Page 111: ...109 3 0 DIMENSIUNI I SPECIFICA II QX 20 EVO QX 20P EVO 7 8...

Page 122: ...120...

Page 124: ...122...

Page 125: ......