17

8

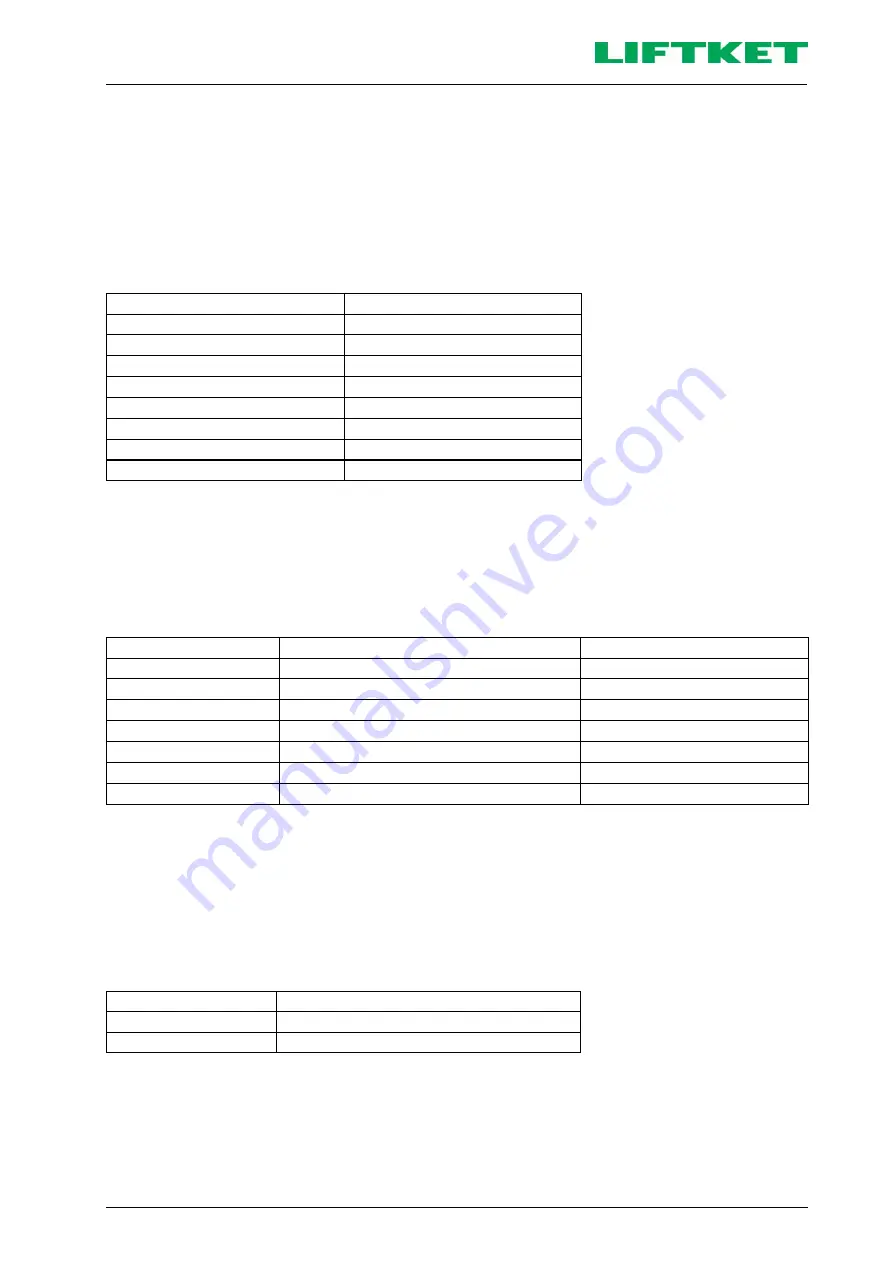

Lubrication

Gear box:

The gear box is already filled with oil by the manufacturer. The oil must be changed if the wire rope winch is going to

be overhauled. The oil has to be disposed in accordance with the law of environmental protection.

Use oil with a viscosity of 220 mm²/s at 40°C and an operating temperature of - 20°C to + 40°C. The necessary

amount of oil is 0.25l.

Alternative oils are:

Supplier

Oil designation

Fuchs

©

Renolin CLP 220

Castrol

©

Alpha Zn 200

ESSO

©

EP 220

Mobil

©

Mobil gear 630

Shell

©

Omala 220

ELF

©

Reductelf SP 220

BP

©

XP 220 BP Energol GR

Exxon Mobil

©

Mobilux EP2

Table 4: Alternative oils

Wire rope:

The rope must be cleaned and lubricated at regular intervals (3 months minimum); if very dirty (concrete, cement) this

work should be done more often.

Supplier

Designation

Application

Elaskon©

Elaskon SK-H

Secondary lubrication

Elaskon©

Elaskon 30

Secondary lubrication

Elaskon©

Elaskon IIISTAR LM

Secondary lubrication

Elaskon©

UNOLIT Spray Öl

Secondary lubrication

Elaskon©

Elaskon Reiniger

Cleaning

Elaskon©

Elaskon Multifunktionsspray SPEZIAL

Multi-function product

Elaskon©

Elaskon MULTI 80

Multi-function product

Table 5: Wire rope care products

Hook tackle:

Lubricate the roller bearing on the hook after approx. 20,000 lifting cycles or once a year. If in heavy use, shorten the

interval and use a special anti-friction bearing grease.

Lubricants recommended for lubrication of bearings:

Supplier

Designation

Fuchs ©

Renolith Duraplex EP3; NLGI - class 3

Fuchs ©

Lagermeister LX EP2

Table 6: Alternative lubricants for bearing