20

2.

When the engine is running, do

not

turn

the

key

to”

”

position to avoid starter motor being

damaged.

3.

When starting, do not rotate the

starter motor for more than 5 seconds at

a time. There should be 120 seconds

between two start.

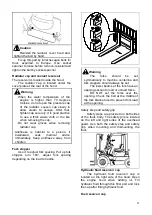

Lift lever [5]

Control the lifting and downing of the

forks.

Push-- down pull--lift

Lifting speed is controlled by tilting

backwards angle of lever and accelerator

pedal. The downing speed can be

controlled by tilting forwards angle of the

lever.

Tilt lever [6]

It is used for forward and backward

tilting of mast.

Push—tilt forward

Pull---tilt backward

The tilting speed is controlled by

tilting angle of the lever and accelerator

pedal effort

Caution

Cause multiway valve equips with

tilt lock valve, when the engine misses,

even push forward the tilting handle

can not tilt forward the mast.

Cup holder[7]

It is in the right side of the instrument. It‟s

designed for the operator to put the cup.

1 Warning light.

:

Press backward, the warning

light is on; press forward, the warning light is

off.

2 Rear headlamp switch

:

Press backward,

the rear headlamp is on; press forward, the

rear headlamp is off.

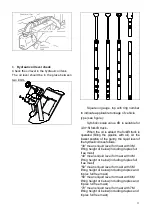

3 2-4 drive switch: press down, convert to

4 drive; press up, convert to 2 drive.

Caution

Four-wheel drive is only used in bad road

conditions or extreme conditions.Use

2-wheel drive when driving normally.

Forklift trucks should be driven by two

wheels when turning on roads, sand,

snow and ice.

4 Differential lock switch: press down,

differential lock; press up, differential

works.

Differential lock is a locking mechanism

installed on the central differential for

four-wheel drive vehicle. Its function is to

improve the passing capacity of forklift in bad

road conditions or extreme conditions, that is,

when a wheel of the forklift idles, the