LIGHT PROGRESS

STICK-ST [eng]

feb-2019

Pag. 6/16

RECEPTION AND ASSEMBLY

Handle with care as fragile material. Verify the integrity of the packaging, and please be careful not to damage the con-

tents when using sharp blades or cutters to open the box.

Remove the unit from the box, then inspect it immediately to ensure that no damage has occurred during transport.

Before installation and use of the device please READ CAREFULLY THE SECURITY WARNINGS and all others in-

structions that follows.

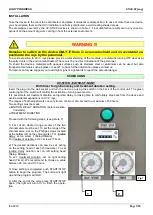

For packaging and transport reasons, the entire unit

comes in two parts: metal stand with wheels, and UV

unit . It is necessary to assemble the UV unit to the

base with the supplied screw kit (picture 2) .

We recommend to follow the following assembly

procedure:

- Place the base plate vertically, like shown on

picture 3, with semicircular side upwards. Align

the top hole with the corresponding hole on the

unit, insert the hex head screw then tighten by

hand or with the aid of a key. Repeat with the

bottom hole (picture 4).

- On the other side of the plate, insert the two hexagonal socket head cap screws into the holes at the bottom of

the control unit (picture 5), then tighten it with the self-locking nuts (picture. 6).

- Firmly tighten the four screws. It is now possible to place the device on its wheels in vertical position, and to

connect the power cable to the dedicated socket on the back of the control unit.

Pic. 2

Pic.3

Pic.5

Pic.4

Pic.6