LIGHT PROGRESS

STICK-ST [eng]

feb-2019

Pag. 8/16

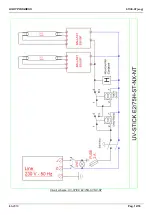

ELECTRICAL CONNECTIONS

We suggest you to let a qualified electrician install this device, following these instructions and the electrical scheme,

as well as CEI norms.

Before connecting the device to the electrical line, make sure that the labelled data on the device are the same as

the ones of the electrical line; we remind you that the electrical supply power of this device is 220-240V, 50/60Hz.

Make sure that the electrical system is capable of providing the supply current required by the device(please read

the label).

The connection to the electrical line needs a multipolar switch.

The connection to the electrical line must be made by the supplied cable.

The use of junction devices in which connection is made via screws, nuts, or other means, is necessary to connect

the device to the electrical line.

Protect the power supply cable from high temperature, sharp corners, water, oils.

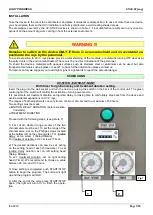

MAINTENANCE

UV LAMP

Lamp maintenance is very important because UV-C light emit-

ted by the source is not visible to the eye, so, although you

see the lamp ON, its germicidal effect may not be sufficient to

performs disinfection treatment.

Before reaching the lamp,

ALWAYS

switch off power supply

If UV-C lamp gets dirty (or gets dusty) clean it with a clean cloth

and alcohol, and avoid touching the glass part with hands. To check

UVC lamp life number of hours, correct product code of the spare

UV lamp please refer to table 1. The lamp, once reached the timing

for replacement,

must be replaced

, this operation is carried out as

follows:

• Loosen the nuts on the lamp housing and let them slide

along the lamp; grab the lamp at the 2 ends and pull it in a

direction parallel to the lamp.

• Repeat the steps in reverse to insert the new lamp.

TROUBLESHOOTING

UV LAMP

See MAINTENANCE.

BALLAST

All UV-DIRECT models are supplied with electronic ballasts which guarantees an emission of 15% more if compared

with traditional ballasts. Furthermore, lamps are not influenced by environment temperature that can goes until -20°C.

Finally, the switching on is immediate, with no starter, and for this reason lamps last longer.

To preserve the original features of original IP protection and isolation class, and to maintain all the characteristics that

guarantee a long lasting life of this product, the ballast replacement must be done by qualified technicians verified by

Light Progress. In case of necessity, please, send the device back to our facility for any kind of repairs.

If this is not possible, you can order the entire power supply conduit for replacement (see Table 1 for code).

USE

PROTECTIVE

GLOVES

WEAR

PROTECTIVE

GLASSES